industrial cleaning wipes factory

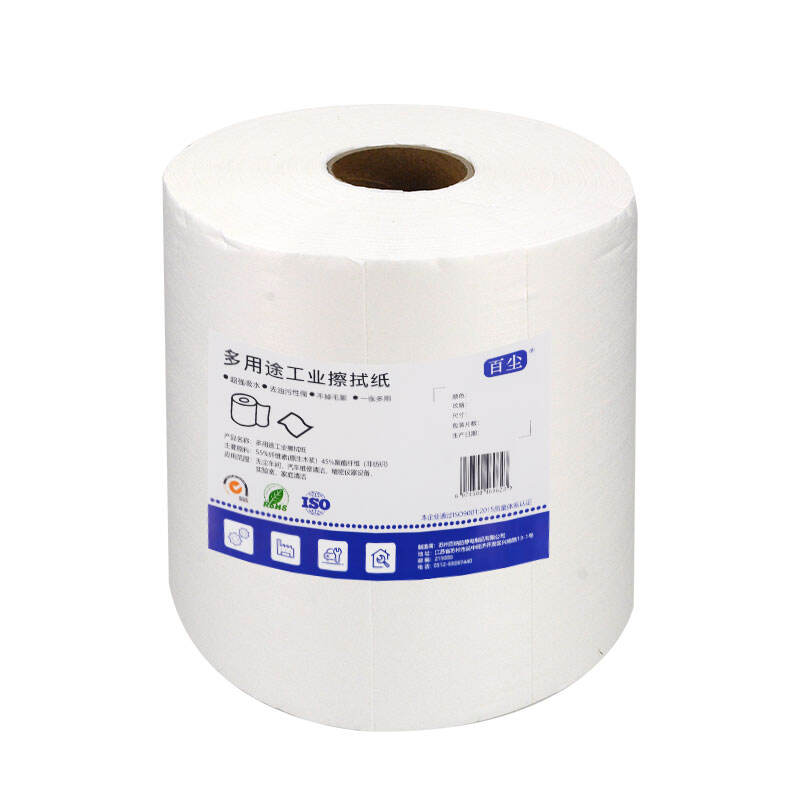

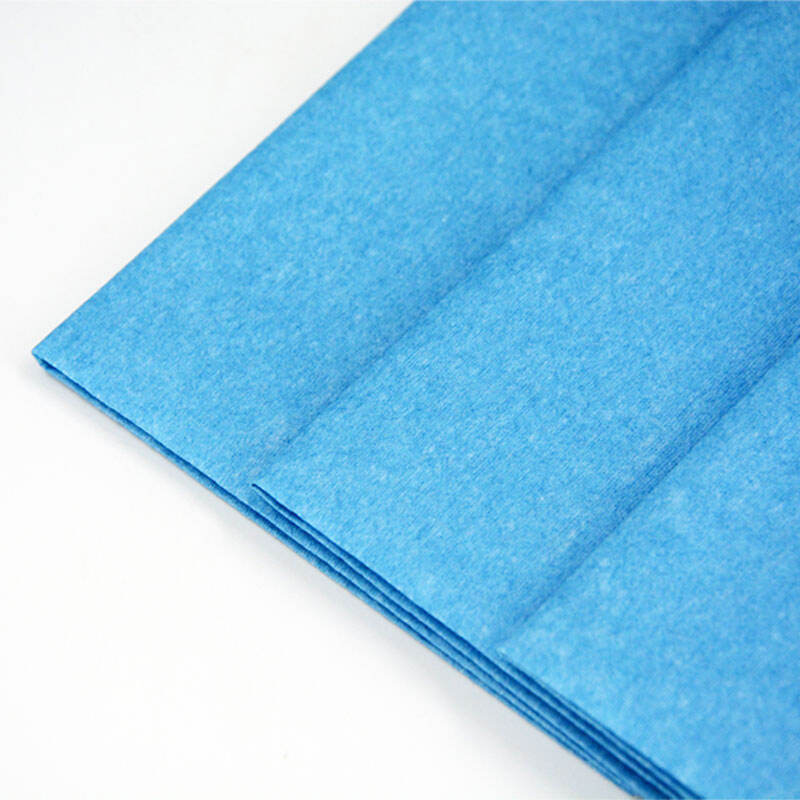

An industrial cleaning wipes factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality cleaning wipes for various industrial applications. The facility incorporates advanced production lines equipped with precision cutting technology, automated folding systems, and quality control mechanisms to ensure consistent product output. The factory utilizes specialized impregnation systems that carefully dose cleaning solutions onto nonwoven materials, maintaining precise saturation levels for optimal cleaning performance. Environmental control systems maintain specific temperature and humidity levels throughout the production area, ensuring product stability and quality. The facility houses dedicated areas for raw material storage, production, packaging, and quality testing laboratories. Modern conveyor systems transport materials efficiently through different production stages, while automated packaging lines ensure precise product counts and secure sealing. Quality control stations feature advanced testing equipment for strength, saturation, and contamination checks. The factory implements strict hygiene protocols and maintains clean room conditions where necessary, particularly for specialized industrial applications. Waste management and recycling systems demonstrate environmental responsibility, while advanced inventory management systems ensure efficient production scheduling and material usage. The facility's versatility allows for the production of various wipe formats, from individual packets to bulk rolls, serving diverse industrial cleaning needs across multiple sectors.