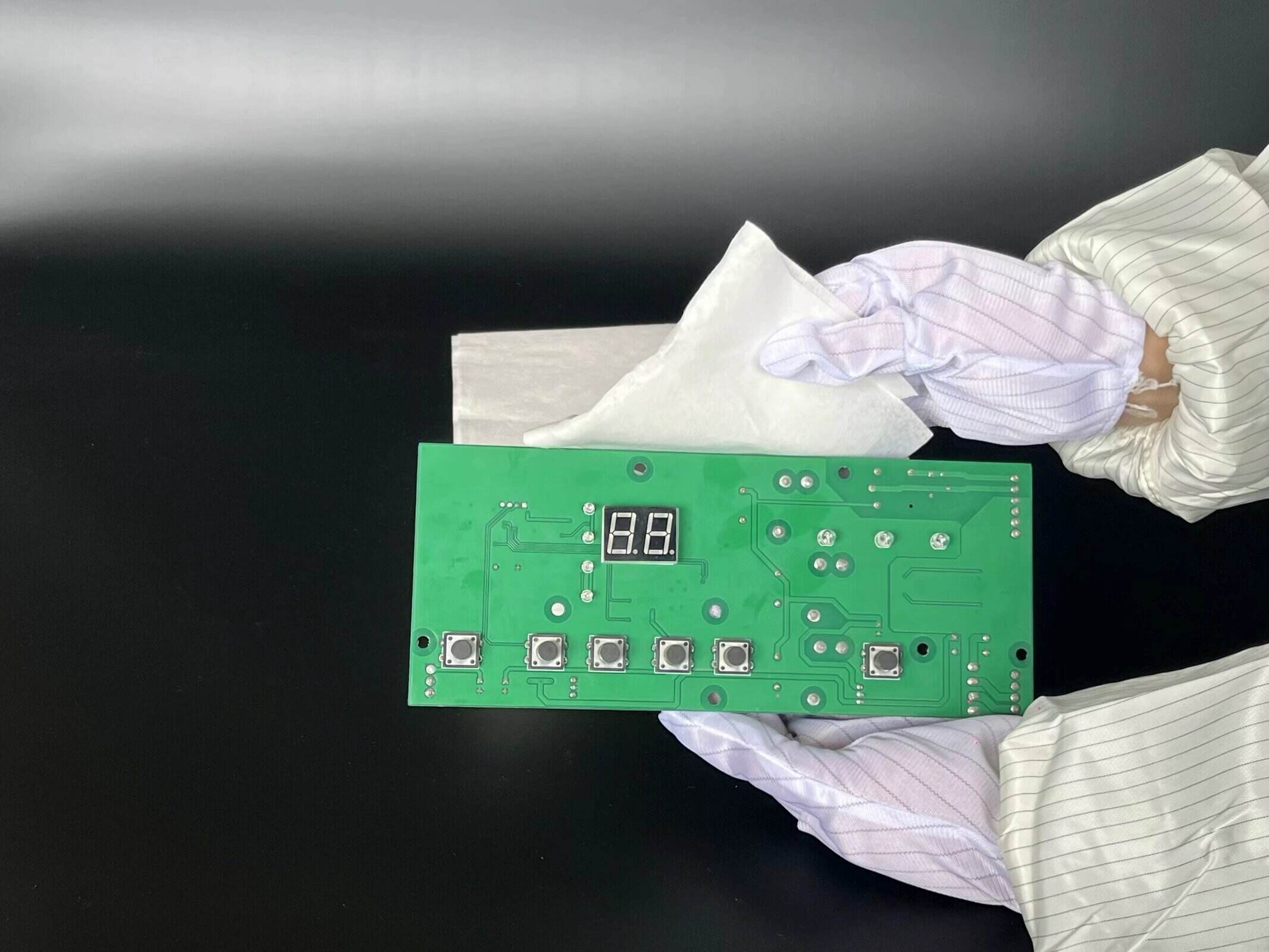

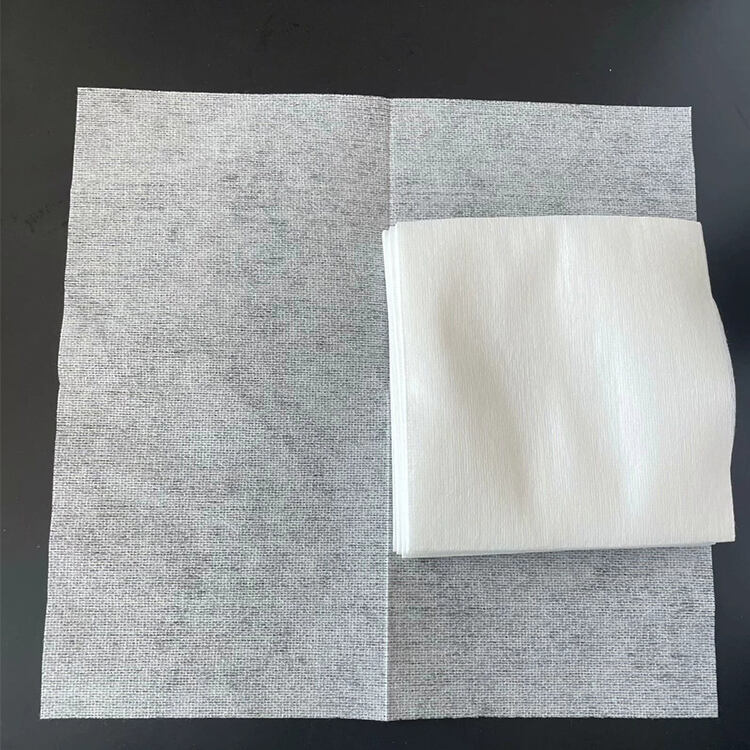

lint free paper manufacturer

A lint free paper manufacturer specializes in producing high quality paper products that are specifically engineered to leave no fibrous residue or particles during use. These specialized facilities employ advanced manufacturing processes that incorporate state of the art filtration systems and precise fiber control mechanisms. The production line utilizes carefully selected raw materials, including premium grade cellulose and synthetic fibers, which undergo rigorous processing to ensure optimal purity and cleanliness. The manufacturing process involves multiple quality control checkpoints, where sophisticated imaging systems and particle detection equipment verify the paper's lint free properties. These manufacturers typically operate in clean room environments to maintain strict quality standards and prevent contamination. The facilities are equipped with automated systems for consistent production, monitoring fiber orientation, density, and surface characteristics. Their products serve critical applications in various industries, including electronics manufacturing, pharmaceutical processing, aerospace components assembly, and precision optical equipment cleaning. The manufacturer's commitment to research and development ensures continuous improvement in production techniques and product performance, while maintaining compliance with international quality standards and industry specific requirements. The facility's quality management system encompasses raw material selection, process control, finished product testing, and comprehensive documentation to ensure traceability and consistency.