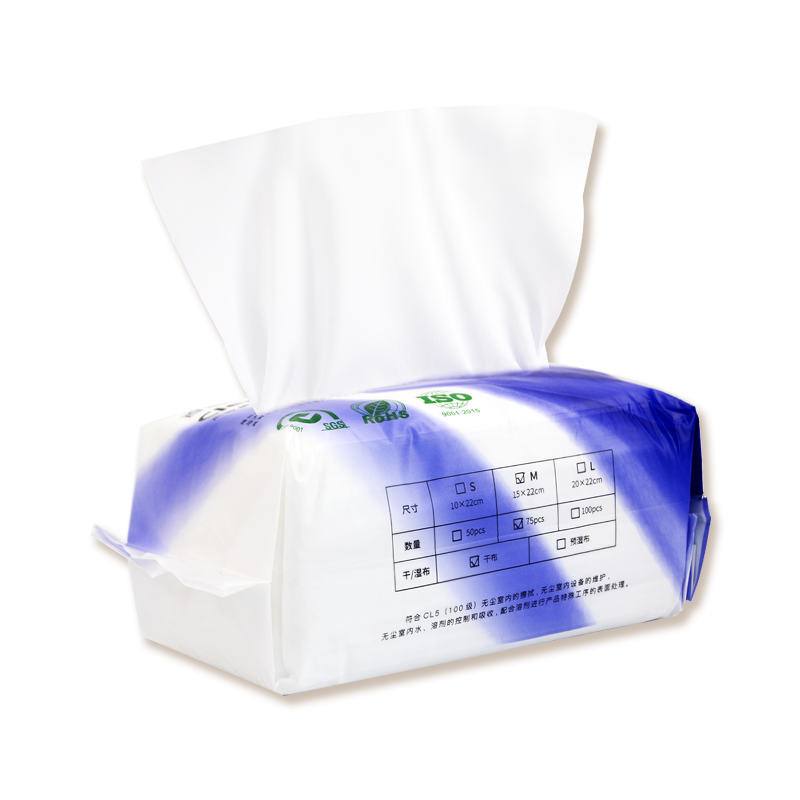

polycellulose wipes manufacturer

A polycellulose wipes manufacturer represents a cutting-edge facility dedicated to producing high-quality, sustainable cleaning solutions for various industries. These specialized facilities incorporate state-of-the-art manufacturing processes that combine cellulose fibers with synthetic polymers to create robust, highly absorbent wipes. The manufacturing process involves advanced fiber formation technology, precision cutting systems, and stringent quality control measures to ensure consistent product quality. These facilities typically feature automated production lines equipped with specialized machinery for fiber blending, web formation, and packaging. The manufacturer's capabilities extend to customizing wipe specifications, including size, thickness, strength, and absorption capacity, to meet diverse customer requirements. Environmental considerations are integrated into the manufacturing process, with many facilities implementing sustainable practices and using eco-friendly materials. The production environment maintains strict cleanliness standards and follows Good Manufacturing Practices (GMP) to ensure product safety and reliability. Quality assurance laboratories within the facility conduct regular testing for physical properties, chemical composition, and performance characteristics. The manufacturer also provides comprehensive documentation and certification services to meet regulatory requirements across different markets and applications. This integrated approach to manufacturing ensures the delivery of premium quality polycellulose wipes that meet the exacting standards of industrial, medical, and consumer applications.