Electrostatic discharge (ESD) is a critical concern in modern manufacturing and electronics production. Uncontrolled ESD can damage sensitive components, reduce production yields, and increase operational costs. Effectively managing ESD is not a single-step process but a systematic engineering approach. A comprehensive solution considers five dimensions: people, requirements, materials, methods, and environment. Addressing ESD across these five dimensions ensures both operational safety and product quality.

People: Training and Protective Clothing

ESD Awareness and Training Programs

Human factors play a major role in ESD management. Employees must be educated about ESD risks and proper handling of sensitive components. Regular training programs help personnel understand the importance of ESD compliance and how individual actions affect overall safety. Operators learn to identify potential hazards and respond appropriately, reducing accidental discharge events.

Protective Clothing and Accessories

ESD clothing is essential to prevent static buildup on personnel. From head to toe, operators can be equipped with ESD coveralls, gloves, shoe covers, and caps. ESD gloves prevent direct contact with static-sensitive devices, while ESD footwear ensures proper grounding. Accessories such as ESD wrist straps provide additional protection at workstations. The combination of clothing and personal grounding devices creates a continuous pathway for static dissipation.

Logistics Handling by Personnel

Proper handling of materials by trained personnel is equally important. Employees must use ESD-safe bags, containers, and transport methods to maintain component protection. Even with advanced equipment, improper handling can undermine the entire ESD control system, making human awareness and adherence to protocols essential.

Requirements: Defining Standards and Workflow

Establishing ESD Protection Standards

Before implementing tools and procedures, it is critical to define ESD protection standards tailored to production needs. These standards cover the acceptable level of electrostatic potential, grounding requirements, and equipment specifications. Clear standards ensure consistency across all workstations and processes.

Workflow Design and Control

ESD protection also relies on proper workflow design. Workstations, storage areas, and assembly lines should be arranged to minimize unnecessary handling of sensitive components. By reducing potential contact points and exposure to static-prone areas, companies can limit ESD risks. Workflow planning integrates seamlessly with both personnel training and equipment selection, creating a comprehensive approach.

Materials: ESD-Safe Tools and Components

Selecting ESD-Compliant Materials

Materials used in production must be carefully selected to prevent static generation. ESD-safe packaging, containers, trays, and bags are essential for storing and transporting sensitive components. Even everyday items like cleaning cloths or wipes should be ESD-compliant to avoid introducing static into production areas.

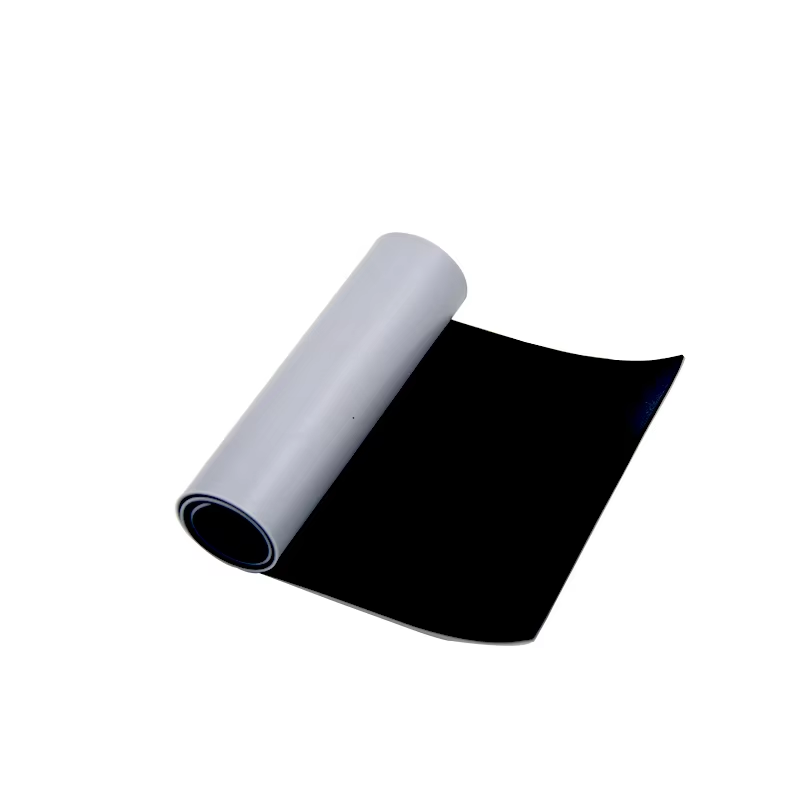

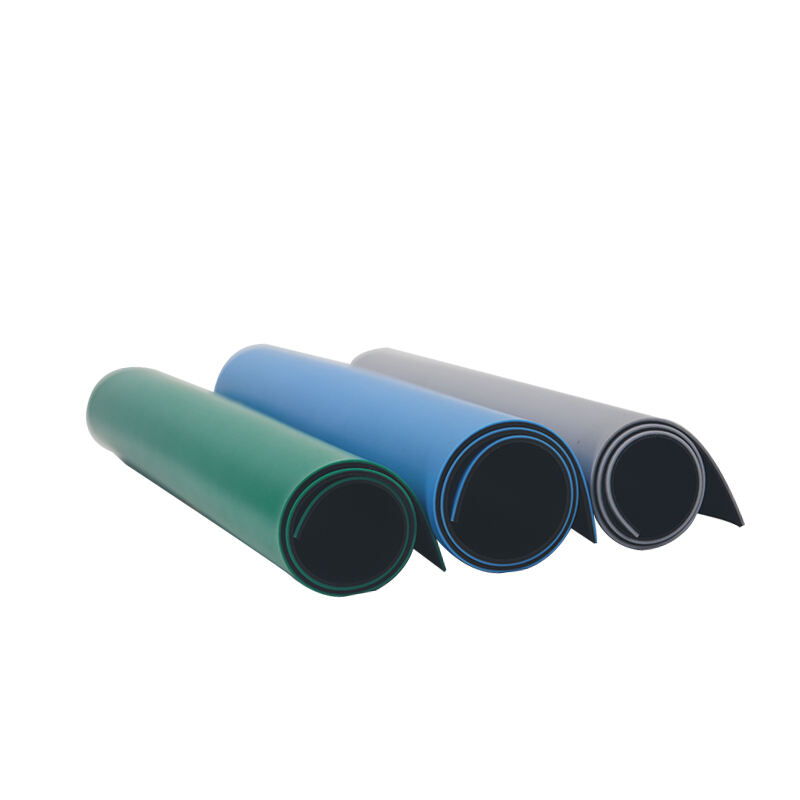

ESD Tools and Workstations

ESD tools form a core part of material control. Workbench mats, ionizers, grounded soldering stations, and wrist straps ensure that components remain protected during handling. Ionizing air blowers neutralize charges on surfaces and in open areas, while ESD mats provide a continuous discharge path for operators and devices. Choosing the right combination of tools maintains consistency and reliability across the production line.

Material Handling Best Practices

Beyond selecting materials, the way they are handled matters. Components should be moved using ESD-safe carts or trays, minimizing contact with non-compliant surfaces. Proper labeling, separation of static-sensitive parts, and controlled transport reduce the risk of accidental discharge, making material handling an integral part of the ESD strategy.

Methods: Procedures and Protocols

Standard Operating Procedures for ESD

Implementing standardized procedures ensures consistent ESD control. Clear protocols cover handling, assembly, inspection, and storage of sensitive components. Employees follow step-by-step instructions to maintain grounding, use protective equipment correctly, and monitor for static accumulation.

Equipment Usage Guidelines

Correct use of ESD tools is essential for effectiveness. Wrist straps must be tested regularly, mats cleaned and grounded, and ionizers calibrated. Guidelines should define testing frequency and troubleshooting steps to prevent lapses in protection. Proper methods extend the lifespan of tools while maintaining ESD safety.

Continuous Monitoring and Improvement

ESD control methods require ongoing monitoring. Regular audits of procedures, employee compliance, and workstation performance help identify weaknesses. Continuous improvement ensures that methods evolve to meet production demands, keeping the ESD control system robust and reliable.

Environment: Controlled Conditions for ESD Safety

Humidity and Airflow Management

The production environment has a direct impact on ESD risks. Low humidity increases the likelihood of static accumulation. Maintaining controlled humidity levels using humidifiers and environmental monitoring systems reduces the potential for electrostatic discharge. Proper airflow design prevents charge buildup and maintains consistent environmental conditions throughout the facility.

Clean Production Areas

Dust and particulate contamination can exacerbate ESD issues. Clean production areas, often supported by HEPA filtration, minimize particles that can interact with static charges. Regular cleaning using ESD-safe wipes and materials further reduces risk. By combining clean environments with proper humidity and airflow, facilities create optimal conditions for ESD control.

Integrated Environmental Systems

An integrated environmental approach includes monitoring temperature, humidity, and air quality. Sensors provide real-time data, enabling immediate corrective actions. Such control ensures that the environment supports ESD protection rather than introducing new risks, making the workspace safer and more reliable for sensitive electronics assembly.

A comprehensive ESD strategy combines protective clothing from head to toe, ESD gloves, ESD wipes, and ionizing air blowers with ESD-safe logistics and handling. Workstations equipped with mats, wrist straps, and properly grounded assembly lines complement these measures, while maintaining controlled humidity in the production environment ensures consistent static protection throughout the facility.