cleanroom wipes 9x9

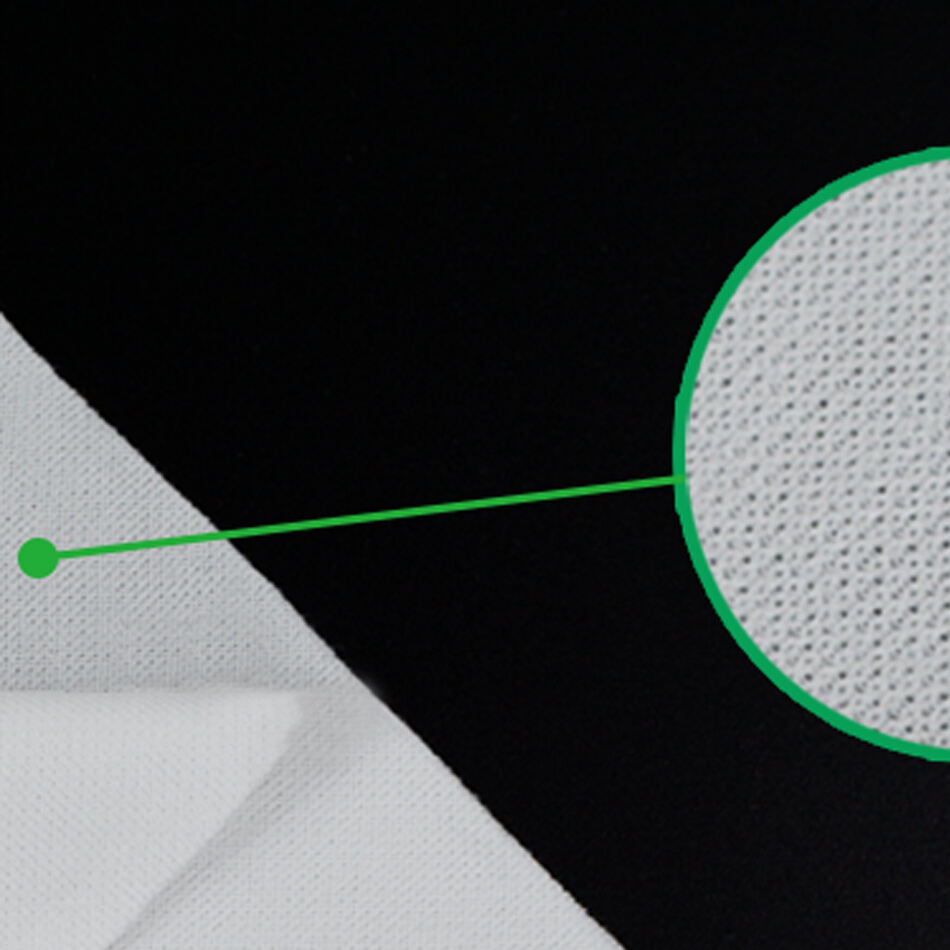

Cleanroom wipes 9x9 represent a critical component in maintaining controlled environments across various industries. These precisely engineered wipes measure 9 inches by 9 inches, offering an optimal size for efficient cleaning and contamination control. Manufactured using advanced polyester blend materials, these wipes are specifically designed to meet the stringent requirements of ISO classified cleanrooms. The wipes feature a unique construction that generates minimal particles during use, making them ideal for critical cleaning applications. Their consistent 9x9 dimensions provide excellent coverage while maintaining ease of use and precise control during wiping procedures. These wipes undergo rigorous quality control processes, including specialized laundering and packaging in controlled environments, ensuring they meet or exceed cleanroom standards. The material composition allows for superior absorption capabilities while maintaining structural integrity, even when used with various cleaning solvents. They excel in removing microscopic particles, oils, and other contaminants from surfaces without leaving residue or generating additional contamination. These professional-grade wipes are suitable for use in semiconductor manufacturing, pharmaceutical production, biotechnology laboratories, and other sensitive environments where maintaining cleanliness is paramount.