microfiber cleanroom wipes

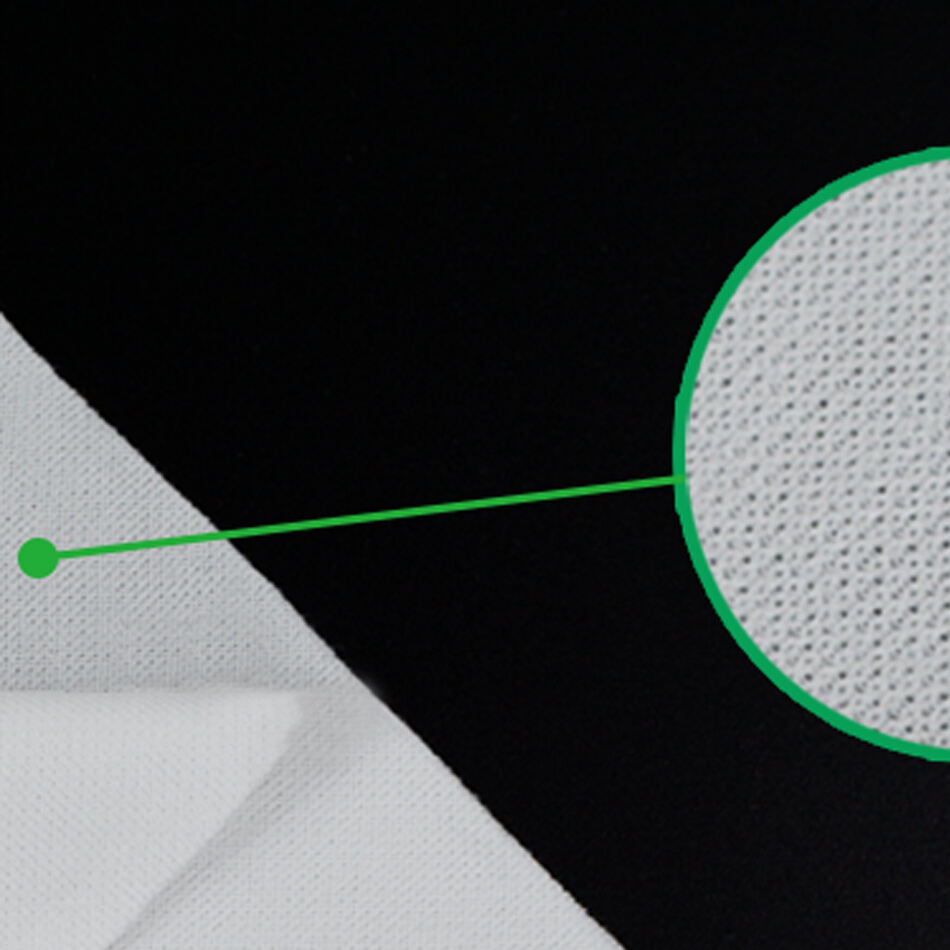

Microfiber cleanroom wipes represent a cutting-edge solution in contamination control and precision cleaning applications. These advanced cleaning tools are engineered from ultra-fine synthetic fibers, typically measuring less than 1 denier in diameter, which are split into microscopic strands creating an exceptional cleaning surface. The unique construction features a blend of polyester and polyamide fibers, woven into a specialized pattern that maximizes particle removal efficiency while minimizing lint and particle generation. These wipes undergo rigorous manufacturing processes in controlled environments to ensure they meet strict cleanroom standards, including ISO Class 4 and above. The distinctive knitted structure creates millions of tiny pockets between the fibers, enabling superior particle entrapment and removal capabilities. These wipes effectively clean surfaces through both dry and wet cleaning processes, demonstrating remarkable absorption capacity for solvents, oils, and other contaminants. Their durability allows for multiple use cycles when properly maintained, offering cost-effective solutions for critical cleaning requirements. The versatility of microfiber cleanroom wipes makes them indispensable in various industries, including semiconductor manufacturing, pharmaceutical production, optical equipment maintenance, and aerospace applications.