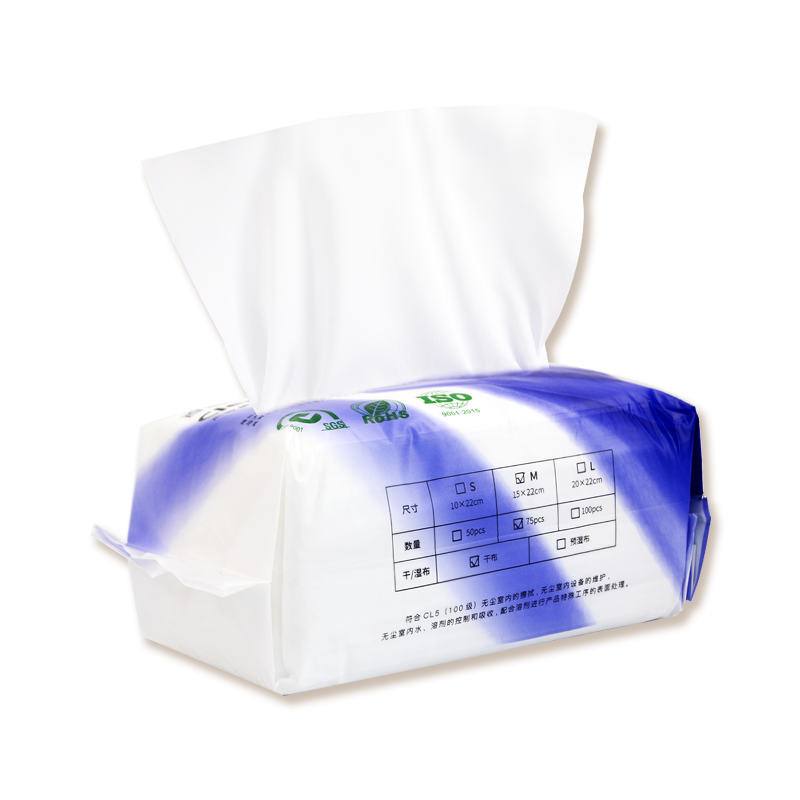

polycellulose wipes factory

The polycellulose wipes factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality, sustainable cleaning solutions. This advanced facility integrates cutting-edge automation systems with precise quality control measures to ensure consistent product excellence. The factory's production line incorporates specialized equipment for spunlace technology, allowing for the creation of durable, lint-free wipes that maintain superior strength when wet or dry. The facility features multiple production lines capable of manufacturing various wipe formats, from industrial-grade cleaning materials to gentle personal care products. Advanced filtration systems and climate-controlled environments ensure the maintenance of strict hygiene standards throughout the production process. The factory's innovative cross-linking technology enables the creation of wipes with enhanced absorption capabilities while maintaining structural integrity. Quality assurance laboratories within the facility conduct continuous testing of raw materials and finished products, ensuring compliance with international standards. The factory's flexible manufacturing capability allows for customization of wipe properties, including thickness, texture, and absorption levels, meeting diverse customer requirements across multiple industries. Environmental sustainability is integrated into operations through water recycling systems and energy-efficient machinery, reducing the ecological footprint of production processes.