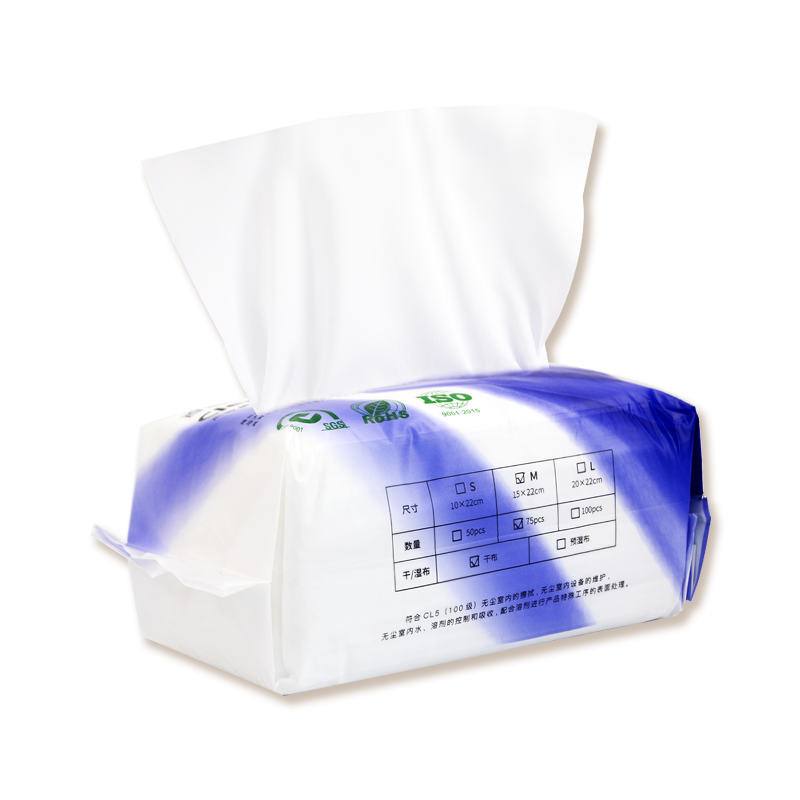

polycellulose wipes made in china

Polycellulose wipes made in China represent a significant advancement in cleaning and industrial applications, combining innovative manufacturing processes with cost-effective production. These wipes are engineered using advanced cellulose-based materials, offering superior absorbency and durability compared to traditional alternatives. The manufacturing process involves specialized techniques that create a unique fiber matrix, ensuring consistent quality and performance across each batch. These wipes feature a distinctive blend of natural and synthetic fibers, providing exceptional strength while maintaining softness and flexibility. The production facilities in China utilize state-of-the-art equipment and quality control measures to maintain high standards. These wipes are particularly effective in various applications, including industrial cleaning, medical settings, and general maintenance tasks. They demonstrate remarkable resistance to tearing and breaking, even when wet, making them ideal for demanding cleaning situations. The wipes' unique composition allows them to effectively trap and remove particles, dust, and liquids while maintaining their structural integrity. Their versatility extends to both wet and dry applications, with excellent compatibility with various cleaning solutions and solvents. Additionally, these wipes are designed to be lint-free, making them suitable for sensitive environments where particle contamination must be minimized.