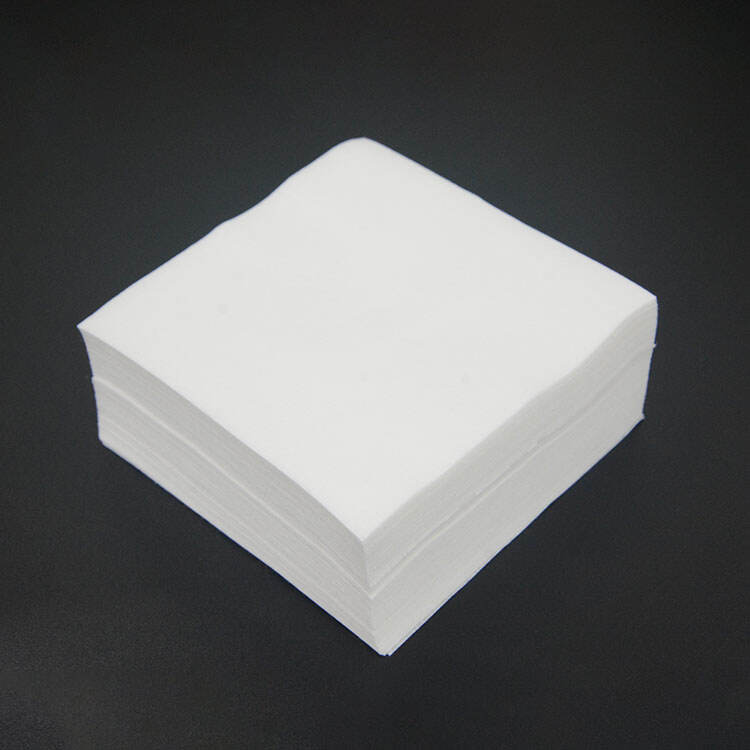

cellulose based cleanroom paper

Cellulose based cleanroom paper represents a crucial advancement in contamination control technology, specifically engineered for critical environments where maintaining cleanliness is paramount. This specialized paper is manufactured using high-grade cellulose fibers that undergo rigorous processing to eliminate potential particulate contamination. The manufacturing process involves multiple stages of purification and treatment, resulting in a product that meets stringent cleanroom standards. The paper's structure features a unique combination of durability and low particle generation, making it ideal for use in ISO-certified cleanrooms across various industries. Its primary functions include documentation, record-keeping, and technical writing in controlled environments where traditional paper products would be unsuitable. The paper's surface is specially treated to minimize fiber release and particle generation during use, while maintaining excellent writing properties and compatibility with various printing technologies. It demonstrates remarkable stability under different environmental conditions and resists degradation when exposed to common cleanroom chemicals. Applications span across pharmaceutical manufacturing, semiconductor production, biotechnology research, aerospace component assembly, and medical device manufacturing facilities. The paper's versatility allows it to serve multiple purposes while maintaining the integrity of cleanroom environments, making it an indispensable tool in modern contamination-controlled operations.