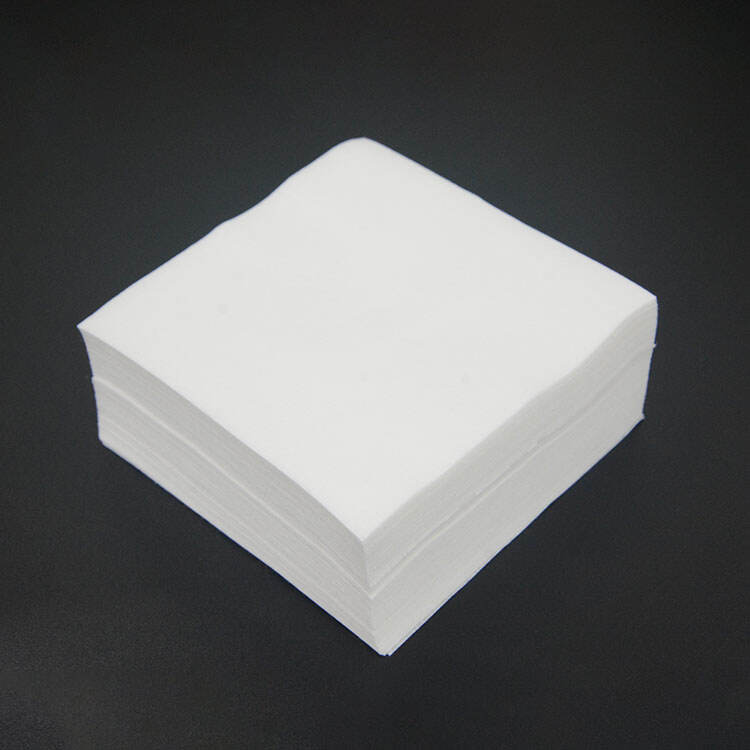

non woven dust free paper

Non woven dust free paper represents a revolutionary advancement in cleaning and industrial applications, engineered specifically to minimize particle generation while maintaining superior cleaning effectiveness. This specialized material is manufactured through a unique bonding process that creates a stable, lint-free structure, making it ideal for environments where contamination control is crucial. The paper's construction involves carefully selected fibers that are mechanically, thermally, or chemically bonded, resulting in a material that maintains its integrity even during vigorous use. It features exceptional absorption capabilities while simultaneously preventing the release of particles or fibers, making it particularly valuable in cleanroom environments, precision manufacturing, and sensitive equipment maintenance. The material's unique properties allow it to effectively capture and retain dust, dirt, and other contaminants without leaving behind any residual particles of its own. This advanced paper combines durability with superior cleaning performance, offering a reliable solution for industries where cleanliness standards are paramount. Its versatile nature makes it suitable for various applications, from electronics assembly to pharmaceutical manufacturing, while its consistent performance helps maintain the integrity of sensitive processes and environments.