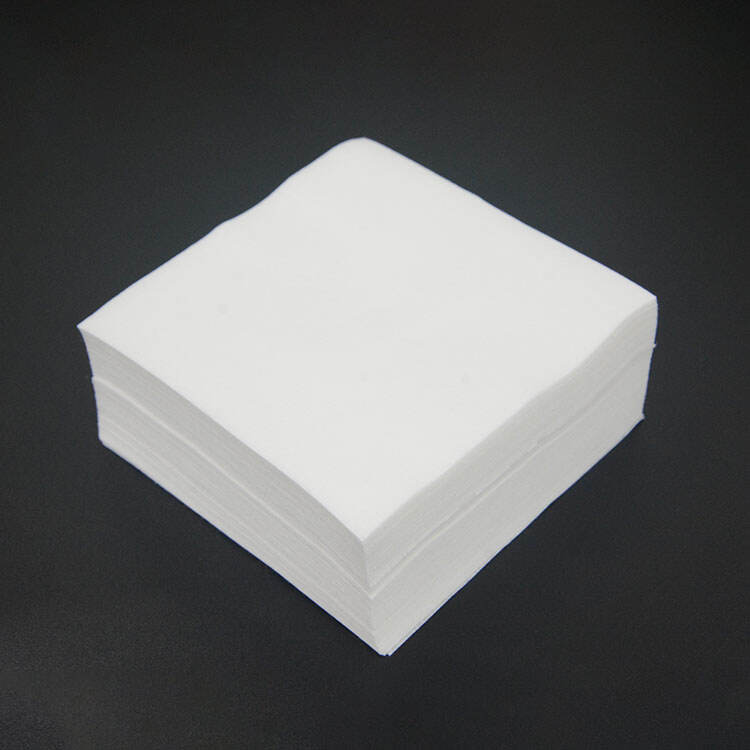

industrial dust free paper

Industrial dust free paper represents a significant advancement in clean room and sensitive manufacturing environments. This specialized paper is engineered to minimize particle generation and contamination risks, making it ideal for use in critical industrial processes. The paper undergoes a rigorous manufacturing process that includes special surface treatments and fiber selection to ensure minimal particle shedding during handling and use. Its unique composition incorporates advanced binding agents that keep fibers tightly locked together, preventing the release of microscopic particles that could compromise sensitive operations. The paper's structure is designed with a smooth, uniform surface that resists abrasion and maintains its integrity even under repeated handling. It features exceptional tensile strength and dimensional stability, allowing it to perform consistently in various industrial applications. The material is particularly valuable in electronics manufacturing, pharmaceutical production, optical component assembly, and other precision industries where particulate contamination must be strictly controlled. The paper's dust-free properties are maintained throughout its lifecycle, from initial handling through final use, ensuring reliable performance in critical clean room environments where even minimal contamination could lead to significant quality issues or production losses.