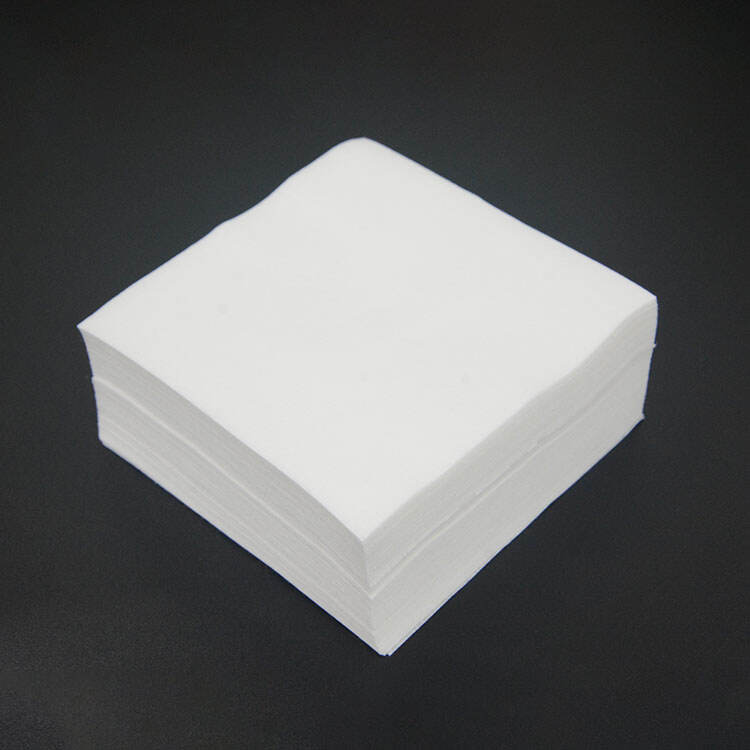

cleanroom paper

Cleanroom paper represents a specialized paper product engineered for use in controlled environments where contamination control is paramount. This innovative material undergoes rigorous manufacturing processes to ensure it meets the stringent requirements of cleanroom operations. The paper is specifically designed to generate minimal particles during use, featuring a unique composition that prevents fiber shedding and maintains structural integrity even under demanding conditions. It incorporates advanced binding technologies that keep fibers securely intact, while special treatments ensure resistance to chemicals and moisture. The material serves multiple functions in cleanroom environments, from documentation and record-keeping to equipment wrapping and process documentation. Its applications span across various industries including semiconductor manufacturing, pharmaceutical production, biotechnology research, and aerospace assembly. The paper's surface is engineered to accept multiple forms of writing implements while maintaining its low-particle-generating properties. It complies with ISO cleanroom standards and undergoes regular testing to ensure consistent performance. Furthermore, it features static-dissipative properties to prevent the attraction and accumulation of particles, making it ideal for sensitive electronic manufacturing environments. The paper's versatility extends to its availability in different formats, including notebooks, individual sheets, and rolls, catering to diverse operational needs while maintaining the highest standards of cleanliness and contamination control.