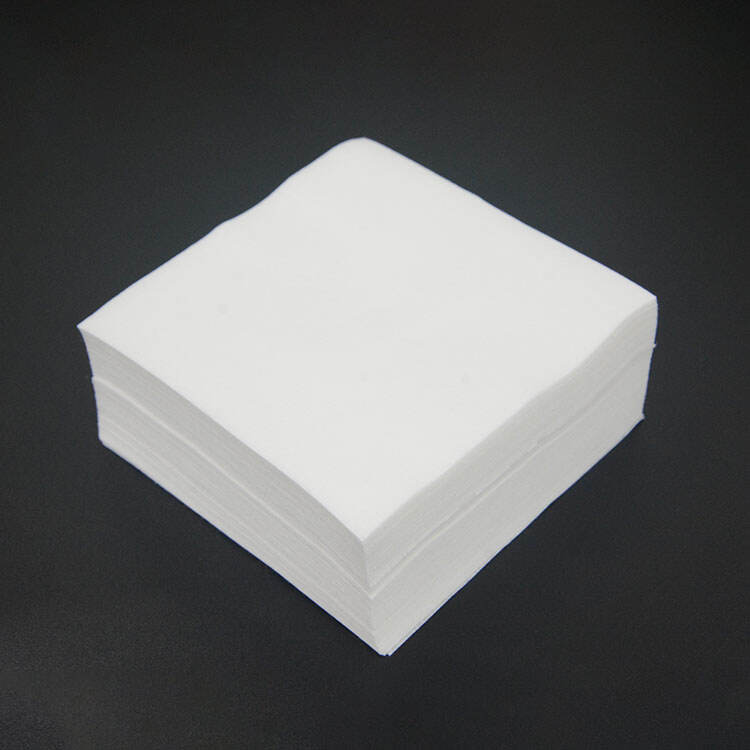

dust free paper

Dust free paper represents a significant advancement in paper manufacturing technology, specifically engineered to minimize particle generation during use. This innovative paper product undergoes a specialized treatment process that binds paper fibers more tightly together, preventing the release of microscopic particles that typically occur with conventional paper handling. The manufacturing process involves a unique coating application that seals the paper's surface while maintaining its essential properties such as writability and printability. The paper's composition includes specially treated cellulose fibers and binding agents that work together to create a stable, low-particulate surface. This specialized paper finds extensive applications in clean rooms, healthcare facilities, pharmaceutical manufacturing, and other environments where contamination control is crucial. The paper's surface stability ensures consistent performance across various applications, from documentation in sterile environments to quality control processes in sensitive manufacturing settings. Additionally, the paper maintains its dust-free properties throughout its lifecycle, from initial handling to long-term storage, making it an ideal choice for applications requiring stringent cleanliness standards.