cleanroom wiper manufacturer

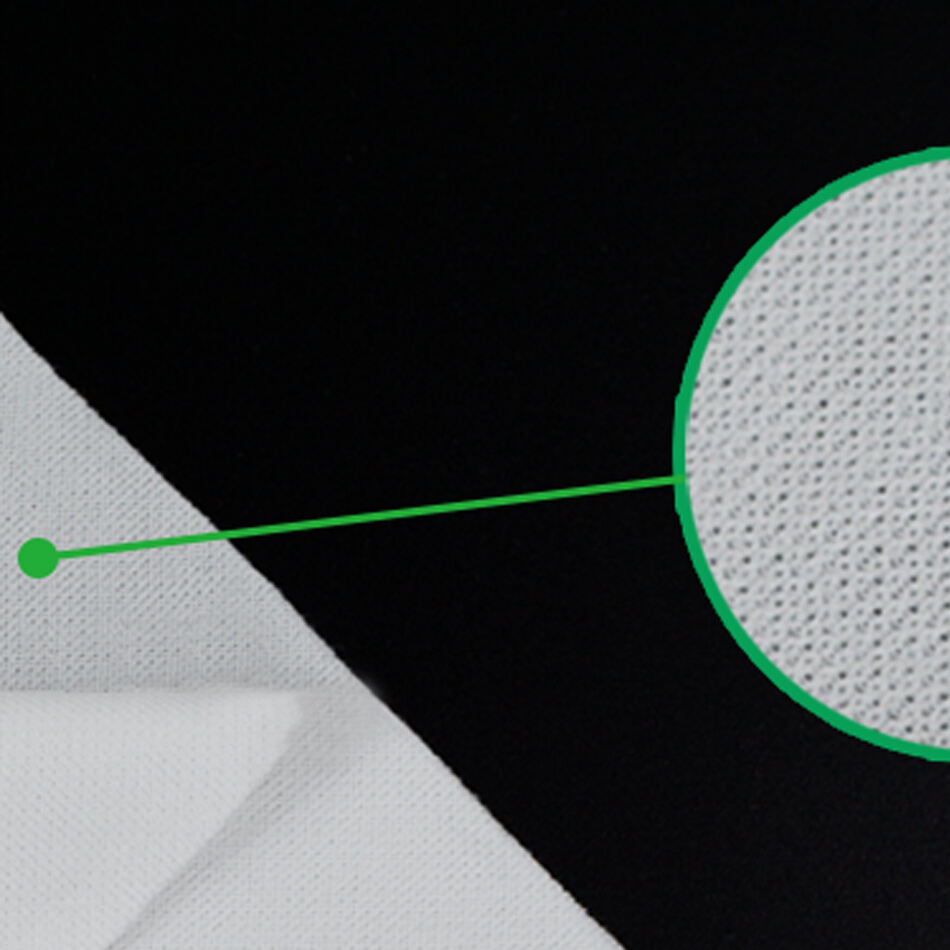

A cleanroom wiper manufacturer specializes in producing high-quality, contamination-free wiping materials essential for maintaining sterile environments across various industries. These manufacturers employ advanced production technologies and stringent quality control measures to create wipers that meet specific cleanliness standards, including ISO classifications. The manufacturing process involves utilizing state-of-the-art equipment in controlled environments to produce wipers from materials such as polyester, microfiber, and cellulose blends. These wipers are engineered to effectively remove particles, chemicals, and other contaminants while generating minimal lint and particles themselves. The facility maintains strict environmental controls, including temperature, humidity, and particle count monitoring, to ensure consistent product quality. The manufacturer's capabilities typically include various wiper formats, from pre-saturated to dry wipers, in multiple sizes and configurations to meet diverse application requirements. Quality assurance protocols include regular testing for particle generation, absorbency, chemical compatibility, and extractables to maintain compliance with industry standards. The manufacturer also provides documentation and certification for their products, ensuring traceability and regulatory compliance for critical cleaning applications in semiconductor, pharmaceutical, biotechnology, and other precision manufacturing industries.