cleanroom wiper made in china

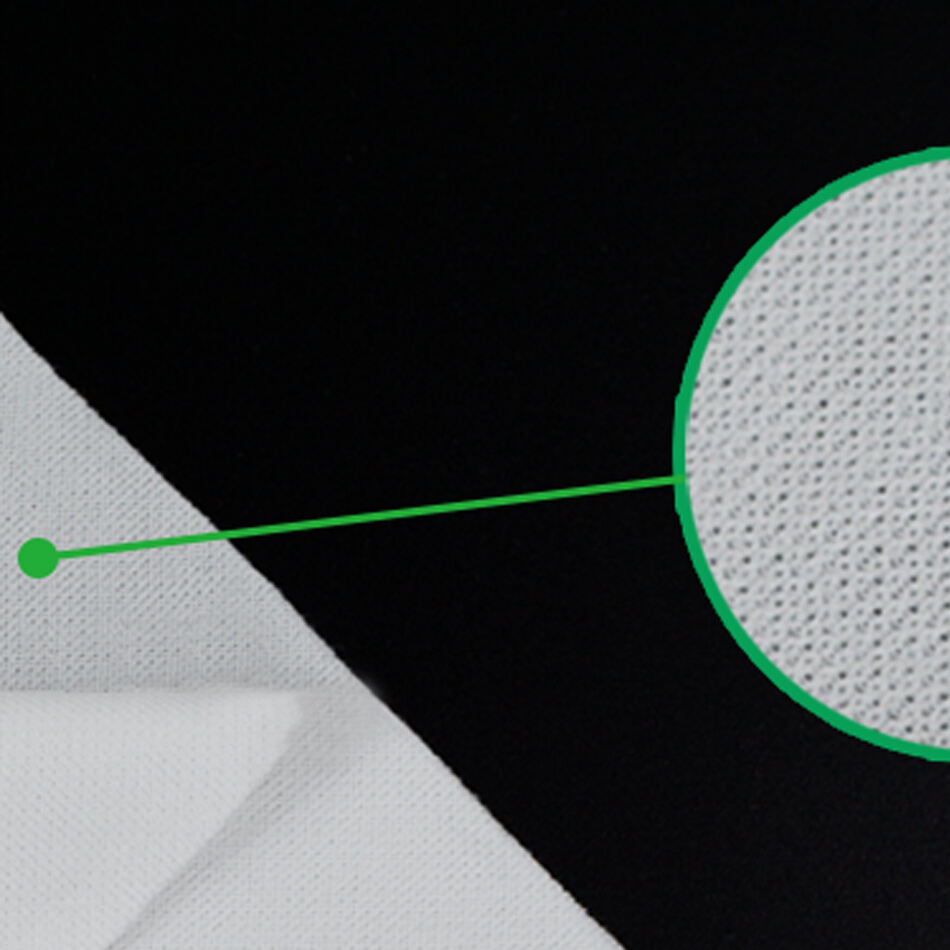

Cleanroom wipers made in China represent a pinnacle of precision manufacturing in contamination control solutions. These essential cleaning tools are specifically engineered to meet the stringent requirements of controlled environments across various industries. Manufactured using advanced production techniques, these wipers feature exceptional particle retention capabilities, minimal particle generation, and superior absorbency characteristics. The production process involves carefully selected materials, typically including polyester, cellulose, or specialized blends, processed in ISO-certified facilities under strict quality control measures. These wipers are designed to effectively remove particles, liquids, and contaminants while preventing secondary contamination. The manufacturing process incorporates ultrasonic cutting technology to prevent edge fraying and reduces particle generation during use. Available in various sizes and configurations, these wipers undergo rigorous testing for particles, fibers, ions, and extractables to ensure compliance with cleanroom standards. They are particularly suitable for critical cleaning applications in semiconductor manufacturing, pharmaceutical production, biotechnology laboratories, and other precision industries. The wipers demonstrate excellent chemical compatibility and maintain their integrity when used with common cleaning solvents and solutions.