durable esd cleanroom wiper

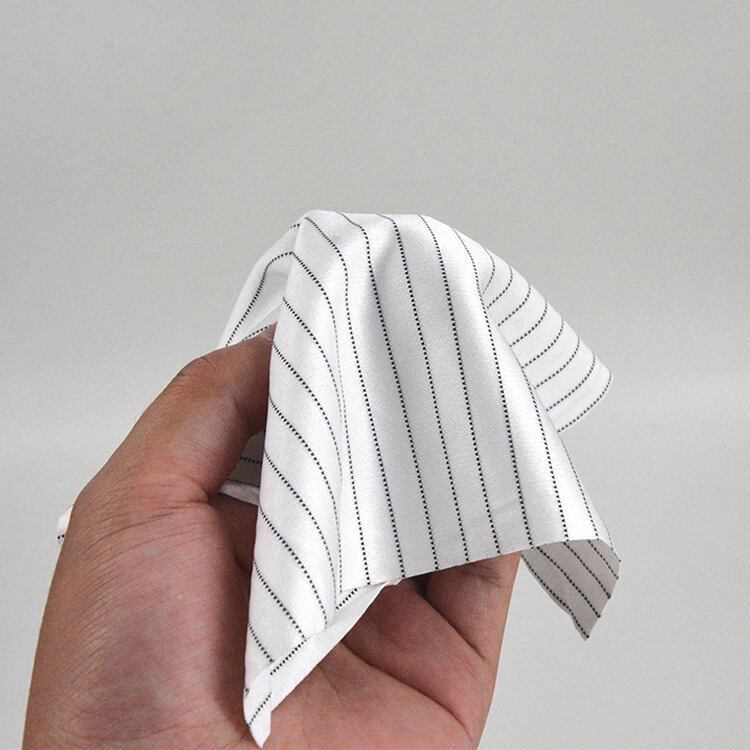

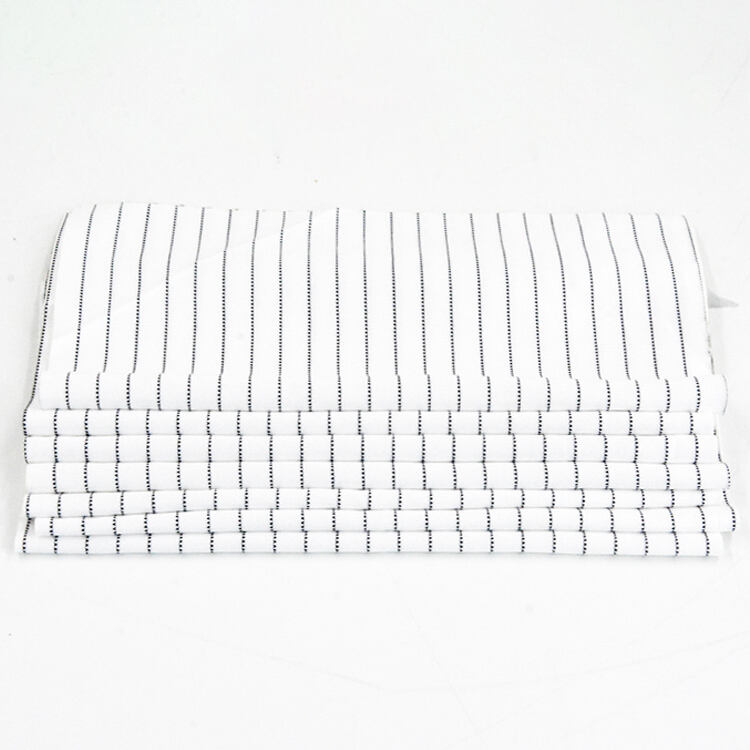

The durable ESD cleanroom wiper represents a cutting-edge solution in contamination control technology, specifically engineered for sensitive environments requiring electrostatic discharge protection. These specialized wipers are manufactured using advanced synthetic materials that combine exceptional durability with superior particle retention capabilities. The unique construction features a blend of polyester and cellulose fibers, treated with proprietary ESD-control agents that maintain consistent electrical properties throughout the wiper's lifecycle. Each wiper demonstrates remarkable strength in both wet and dry conditions, making it ideal for multiple cleaning applications. The material's inherent strength allows for aggressive cleaning without deterioration or particle generation, while its controlled conductivity prevents static buildup that could damage sensitive electronic components. These wipers are particularly effective in ISO Class 4-8 cleanrooms, semiconductor manufacturing facilities, and precision electronics assembly areas. The advanced edge treatment prevents fiber release and ensures consistent performance across the entire surface area. With their ability to maintain cleanliness standards while protecting against electrostatic discharge, these wipers have become essential tools in modern cleanroom operations.