best esd cleanroom wiper

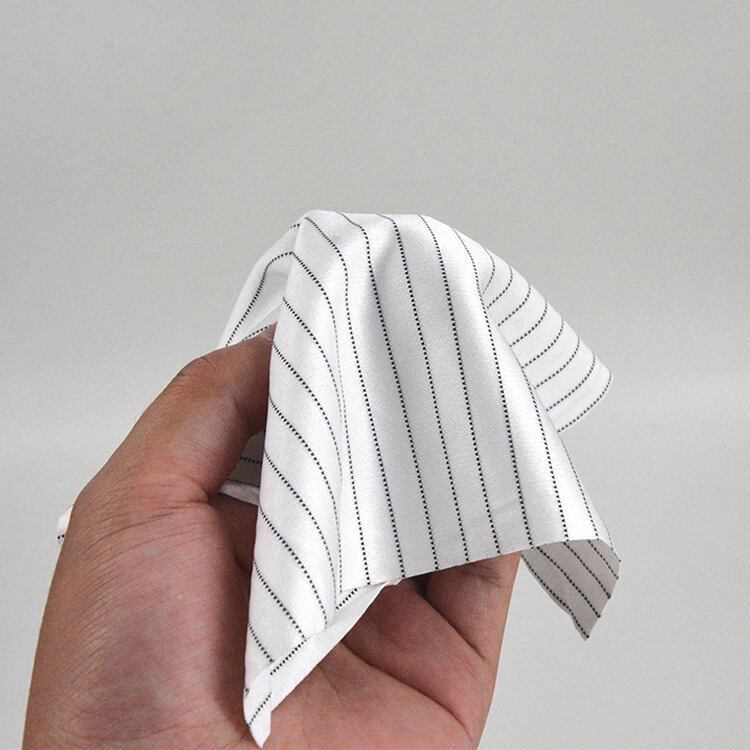

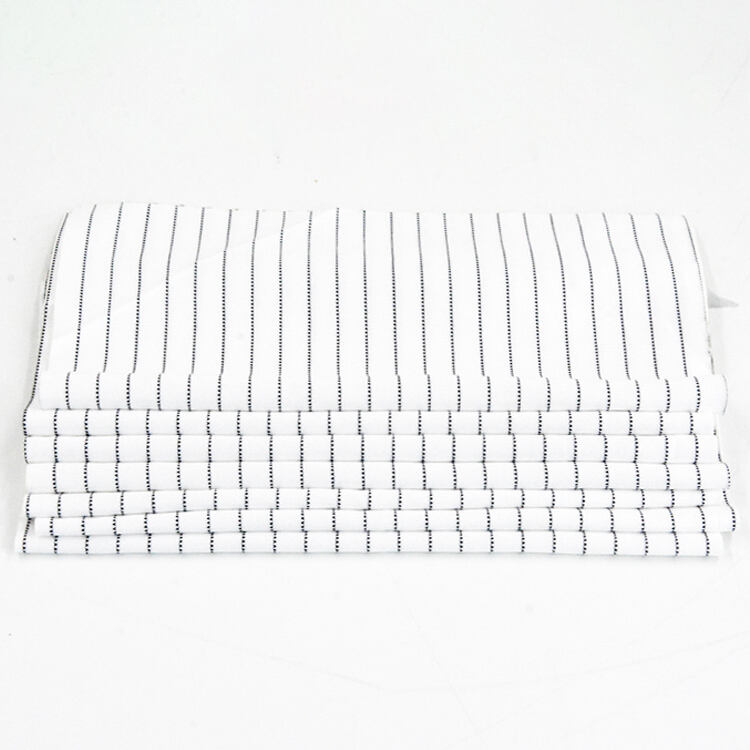

The best ESD cleanroom wiper represents the pinnacle of contamination control technology, specifically engineered for critical environments where electrostatic discharge control is paramount. These specialized wipers are manufactured using innovative polyester and cellulose blend materials, ensuring superior particle removal while maintaining exceptional static dissipative properties. With a typical surface resistivity range of 10^6 to 10^9 ohms per square, these wipers effectively prevent static charge buildup during cleaning operations. The material undergoes rigorous laundering processes in ultra-clean facilities, resulting in remarkably low particle generation and ion content. Each wiper features sealed edges using advanced ultrasonic cutting technology, preventing fiber release and maintaining cleanroom integrity. These wipers demonstrate exceptional absorption capacity, capable of handling both aqueous and solvent-based solutions while maintaining their ESD properties. They are particularly suited for Class 100 (ISO 5) cleanrooms and below, making them ideal for semiconductor manufacturing, aerospace applications, and sensitive electronic assembly operations. The wipers maintain their effectiveness through multiple uses, providing cost-effective contamination control while ensuring consistent static discharge protection.