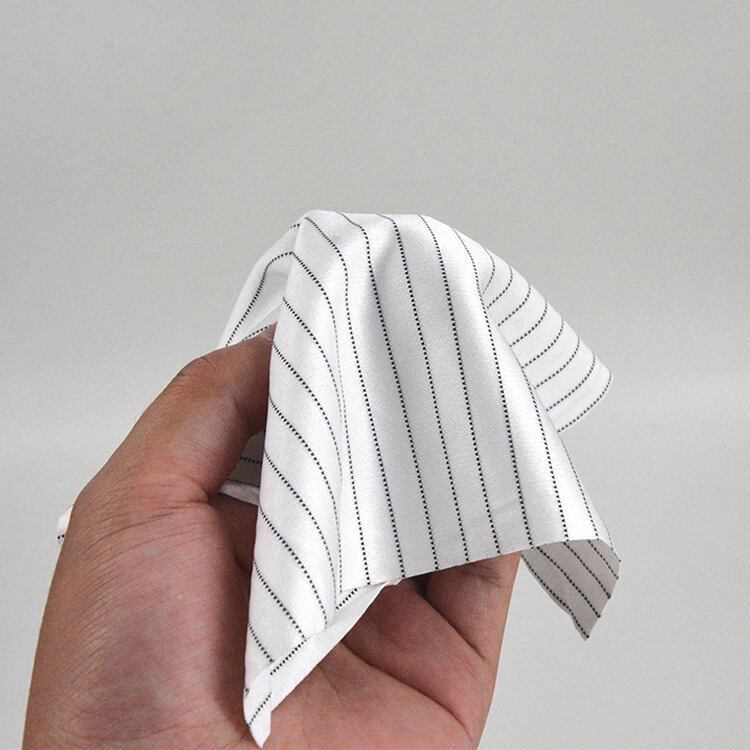

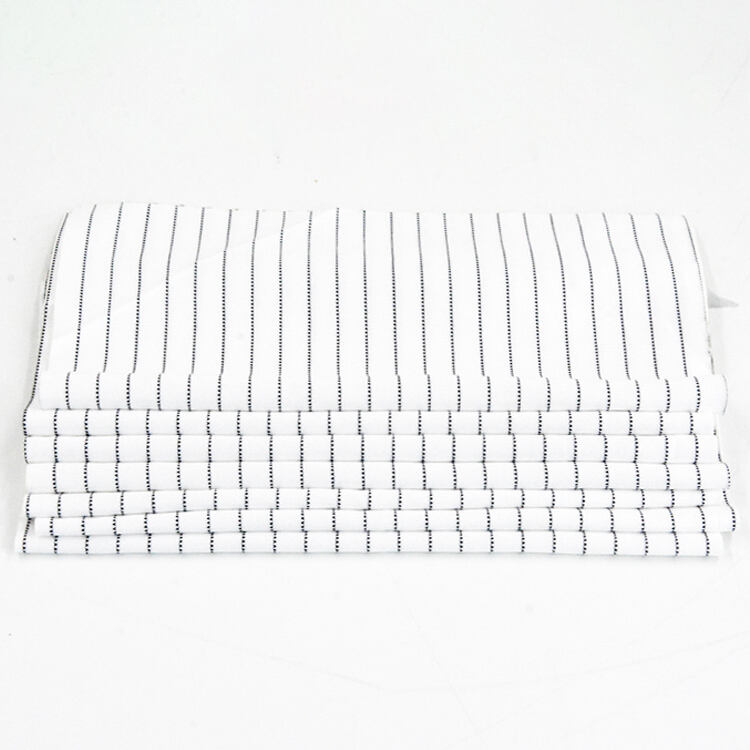

esd cleanroom wiper made in china

ESD cleanroom wipers made in China represent a critical component in maintaining contamination-free environments across various industries. These specialized wipers are engineered with advanced static-dissipative properties, effectively preventing electrostatic discharge while ensuring superior particle removal. Manufactured under strict quality control measures, these wipers feature a unique blend of synthetic materials, typically combining polyester with cellulose or other specialized fibers. The construction process involves ultrasonic sealing techniques that minimize particle generation and fiber release. Each wiper undergoes rigorous testing to ensure compliance with cleanroom standards and ESD protection requirements, maintaining a surface resistivity range of 10^6 to 10^11 ohms per square. The wipers excel in removing microscopic particles, oils, and other contaminants while preventing static buildup that could damage sensitive electronic components. Their application extends across semiconductor manufacturing, pharmaceutical production, aerospace assembly, and other precision industries. The wipers are available in various sizes and packaging options, each designed to maintain cleanliness and ESD protection throughout their use cycle. Quality assurance processes include particle count testing, extractables analysis, and ESD performance verification, ensuring consistent performance in critical environments.