esd cleanroom wiper price

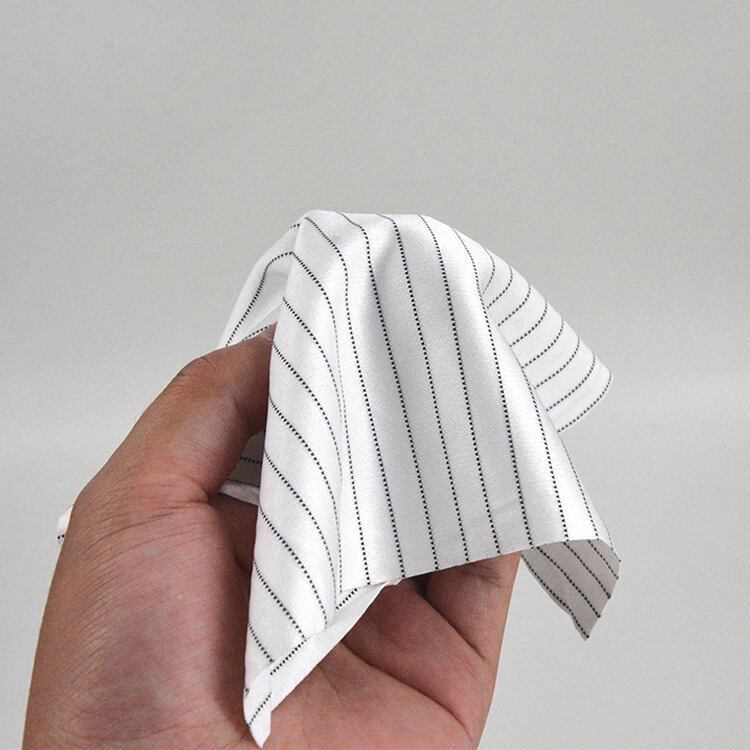

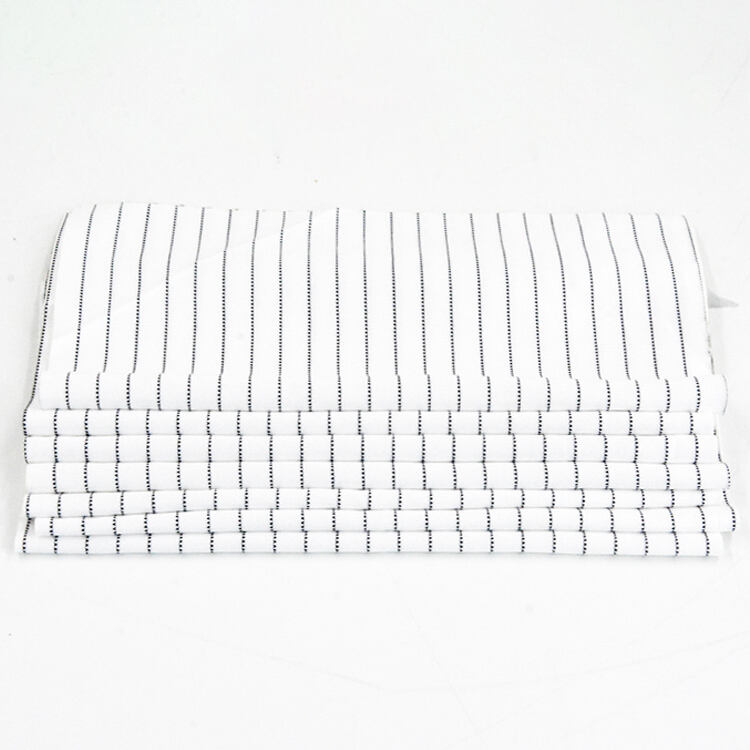

ESD cleanroom wipers represent a critical investment in maintaining contamination-free environments, with prices reflecting their specialized manufacturing and quality assurance processes. These advanced wipers are specifically designed to prevent electrostatic discharge while maintaining superior particle and residue removal capabilities. The price point of ESD cleanroom wipers varies based on factors such as material composition, size specifications, and quantity ordered. Typically manufactured using synthetic materials like polyester or cellulose blends with specialized ESD-safe treatments, these wipers offer consistent performance in controlling static electricity while meeting stringent cleanliness requirements. The pricing structure often accounts for features such as ultra-low particle generation, exceptional absorbency, and compatibility with various solvents commonly used in cleanroom environments. When considering the ESD cleanroom wiper price, it's essential to factor in their role in protecting sensitive electronic components and maintaining the integrity of cleanroom operations. The cost reflects advanced manufacturing processes that ensure each wiper meets specific static dissipative properties and cleanliness standards required for critical environments.