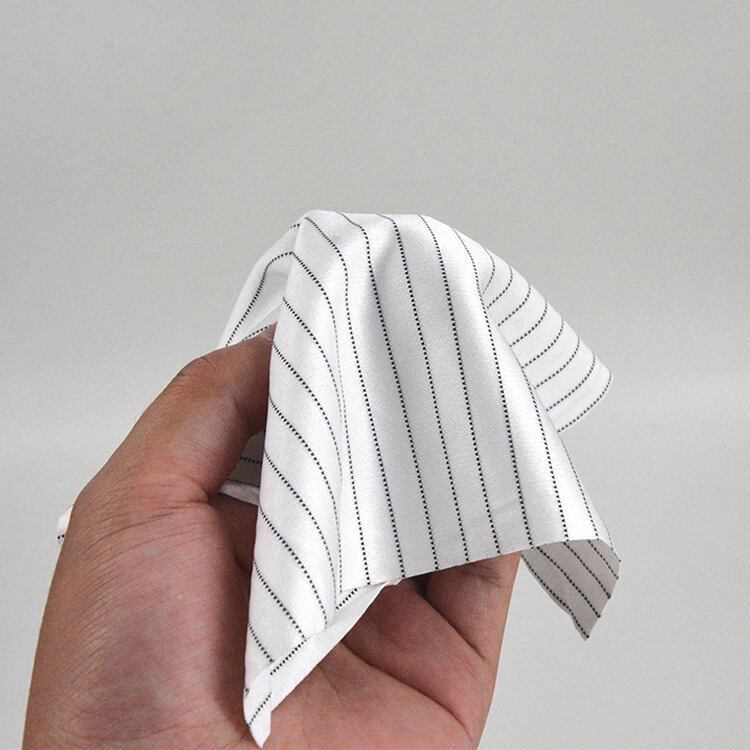

safe esd cleanroom wiper

The safe ESD cleanroom wiper represents a critical tool in controlled environments, engineered specifically for sensitive electronic manufacturing and cleanroom operations. This specialized wiper combines essential static dissipative properties with superior cleaning capabilities, making it indispensable for maintaining pristine conditions in critical environments. Constructed from high-quality polyester and cellulose blend materials, these wipers effectively control electrostatic discharge while maintaining exceptional particle retention capabilities. The wipers undergo rigorous manufacturing processes, including edge sealing and specialized treatments, to ensure minimal particle generation and superior cleanliness levels. Their unique composition allows for effective removal of contaminants, oils, and particulates while preventing static buildup that could potentially damage sensitive electronic components. These wipers are validated for use in ISO Class 4-8 cleanrooms and feature consistent static dissipative properties throughout their entire structure. The material's durability ensures sustained performance even under demanding cleaning protocols, while its low particle and fiber release characteristics make it ideal for critical cleaning applications. Each wiper undergoes strict quality control measures, including particle counting and charge decay testing, to ensure compliance with cleanroom standards.