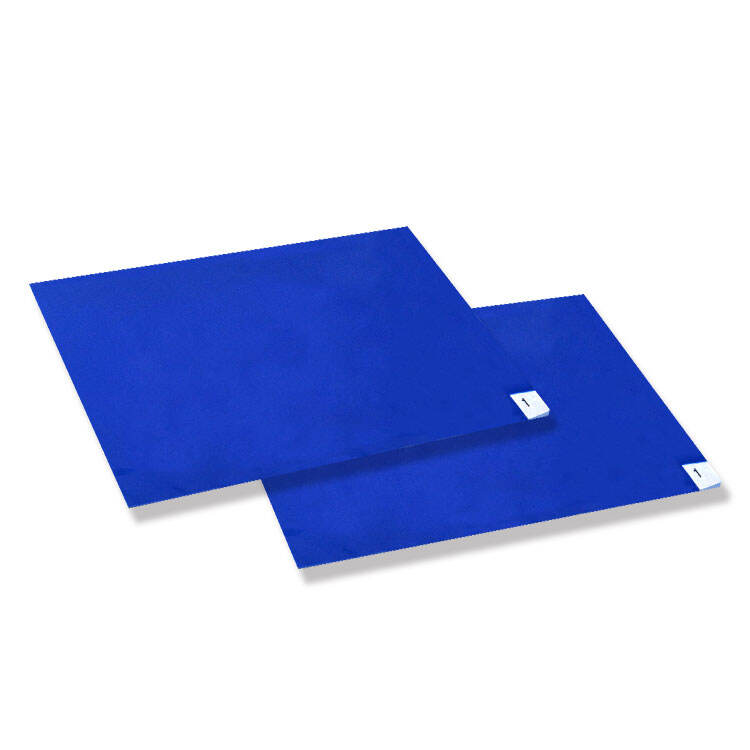

esd sticky mat

An ESD sticky mat is a specialized floor protection solution designed to prevent electrostatic discharge in sensitive environments. These mats feature multiple adhesive layers that effectively capture dust, dirt, and other particulates from footwear and wheel traffic. The mat's construction typically consists of 30-40 numbered layers, each made with anti-static materials that help dissipate static electricity safely. When the top layer becomes saturated with contaminants, it can be easily peeled away to reveal a fresh, clean surface underneath. These mats are commonly installed at entrances to cleanrooms, laboratories, and electronic manufacturing facilities, where they serve as the first line of defense against contamination and static electricity. The mat's surface is engineered with a carefully calibrated adhesive that's strong enough to trap particles but won't transfer residue to shoes or equipment. Each layer is treated with special static-dissipative compounds that maintain a consistent electrical resistance throughout the mat's lifetime. The mats are available in various sizes and configurations to accommodate different doorway dimensions and traffic patterns, with some models featuring custom-cut options for specific space requirements.