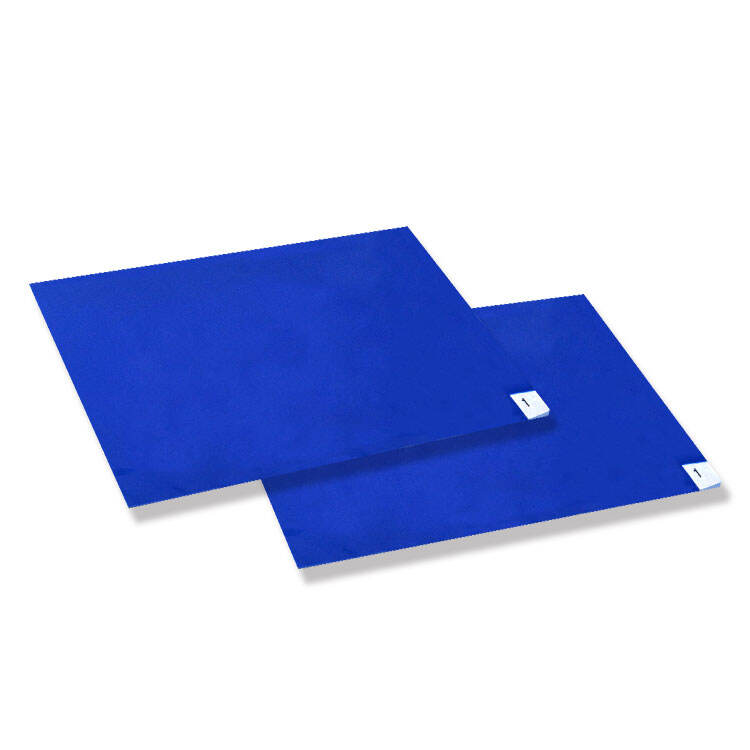

esd sticky mat manufacturer

An ESD sticky mat manufacturer specializes in producing high-quality contamination control solutions designed to protect sensitive electronic components and clean room environments. These manufacturers employ advanced production techniques to create multi-layered adhesive mats that effectively capture and retain dust, dirt, and other particulates from foot traffic and wheeled equipment. The manufacturing process involves precise layering of specially formulated adhesive sheets, typically consisting of 30 to 40 individual peel-off layers, each treated with static-dissipative properties. Modern ESD sticky mat manufacturers utilize state-of-the-art production facilities equipped with controlled environments to ensure consistent quality and performance. They implement rigorous quality control measures, including conductivity testing, adhesive strength verification, and durability assessments. These manufacturers often integrate innovative features such as numbered layers for easy tracking, color-coding options for different zones, and specialized edge treatments to prevent curling and tripping hazards. The production process also includes the application of anti-microbial treatments and careful selection of materials that maintain their effectiveness under various environmental conditions. Leading manufacturers provide customization options, including size specifications, adhesive strength variations, and branding possibilities to meet specific customer requirements.