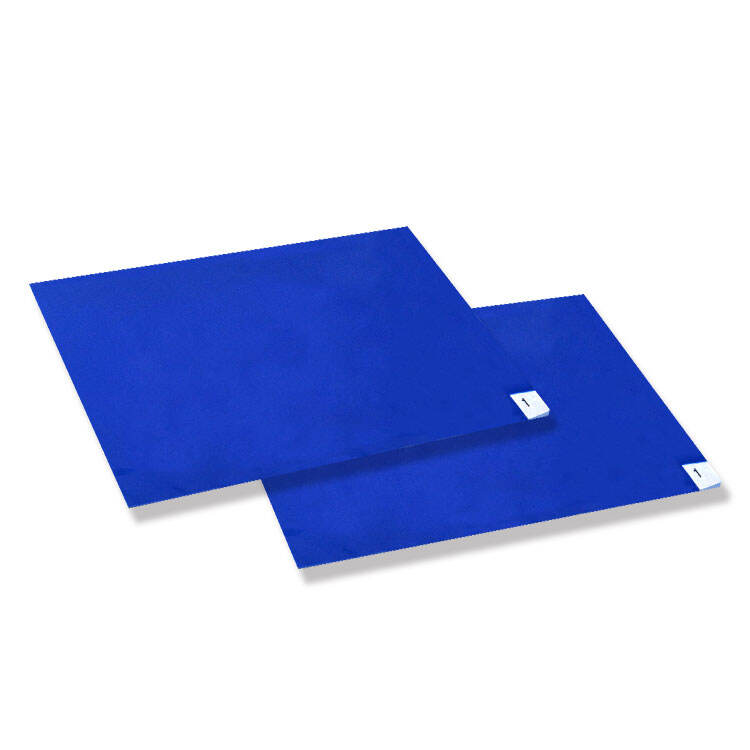

high quality esd sticky mat

The high quality ESD sticky mat represents a cutting-edge solution for maintaining clean room environments and protecting sensitive electronic components from electrostatic discharge. This specialized mat features multiple layers of adhesive sheets that effectively capture and retain dust, dirt, and other microscopic particles from footwear and equipment wheels. Each mat is constructed with specialized polymers that ensure consistent electrical conductivity, maintaining a resistance range of 108-1011 ohms, which effectively dissipates static charges while preventing the accumulation of potentially harmful electrostatic energy. The mat's surface is designed with a perfect balance of tackiness, strong enough to trap contaminants but gentle enough to allow easy movement. Available in various sizes and colors, these mats are typically placed at entrances to clean rooms, assembly areas, and other critical environments where contamination control is paramount. The innovative peeling system allows for easy removal of soiled layers, revealing a fresh, clean surface underneath, which extends the mat's operational life and maintains optimal performance. These mats are particularly valuable in industries such as electronics manufacturing, semiconductor production, pharmaceutical processing, and precision assembly operations where maintaining a contamination-free environment is crucial for product quality and operational success.