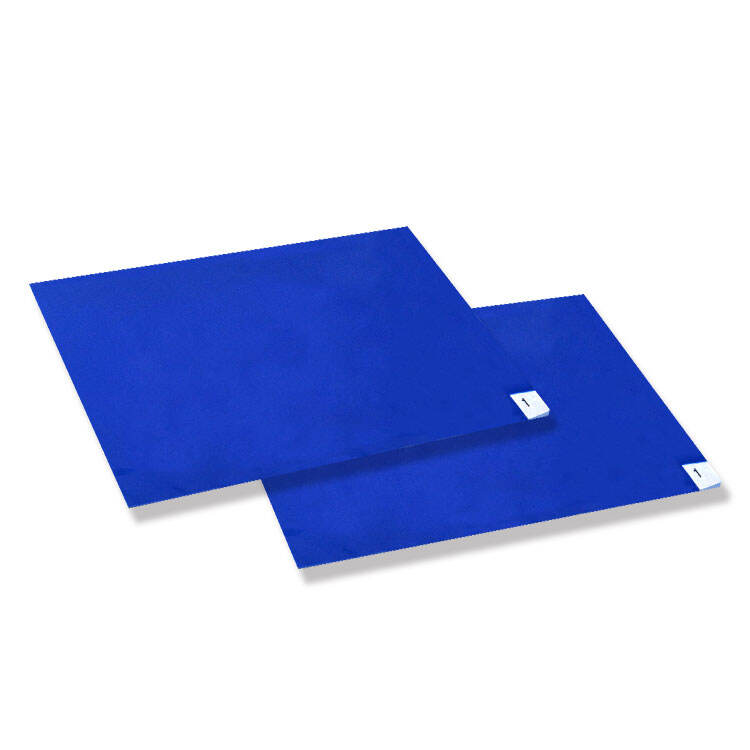

esd sticky mat for sale

The ESD sticky mat for sale represents a crucial component in maintaining cleanliness and static control in sensitive environments. This specialized mat features multiple layers of adhesive sheets that effectively capture dust, dirt, and other particulates from footwear and equipment wheels before they enter clean areas. Each mat is constructed with dissipative materials that help prevent the buildup of static electricity, making it essential for electronics manufacturing, laboratories, and cleanroom facilities. The mat's adhesive layers are precisely engineered to provide optimal tackiness without leaving residue on shoes or wheels, while being strong enough to trap contaminants effectively. When one layer becomes saturated with debris, it can be easily peeled away to reveal a fresh, clean surface underneath. The mats are available in various sizes to accommodate different entryway dimensions and traffic patterns, with most options featuring numbered sheets for easy tracking of remaining layers. The construction includes a non-slip backing that ensures the mat stays firmly in place during use, enhancing safety and effectiveness. These mats are designed to withstand heavy foot traffic while maintaining their static-dissipative properties throughout their service life.