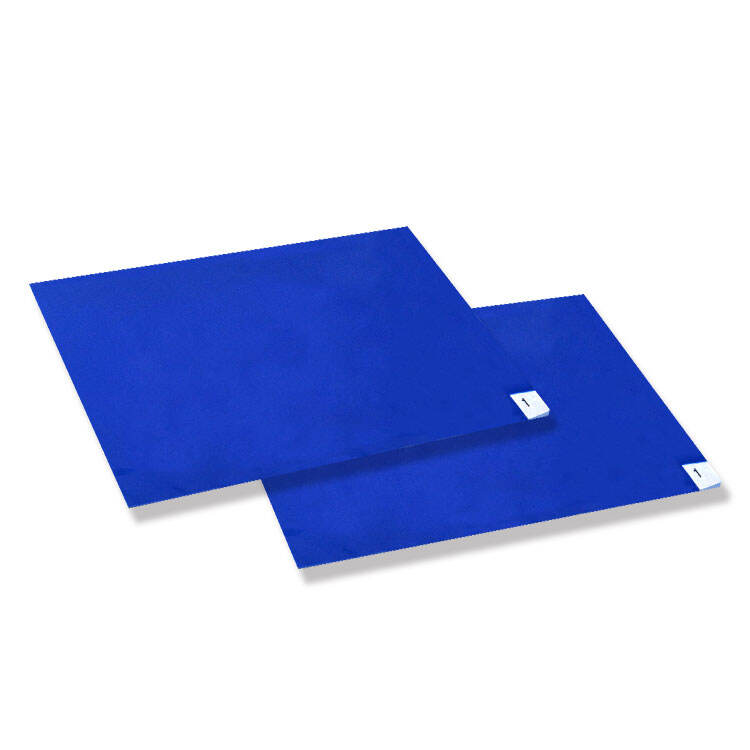

esd sticky mat made in china

The ESD sticky mat made in China represents a cutting-edge solution for maintaining clean room environments and protecting sensitive electronic components from electrostatic discharge. These specialized mats feature multiple layers of adhesive sheets that effectively capture dust, dirt, and other particulates from footwear and wheel traffic. Manufactured using advanced polymer technology, these mats incorporate specialized conductive materials that dissipate static electricity safely to the ground. Each mat typically consists of 30 to 40 removable layers, with each layer numbered for easy tracking and replacement. The surface adhesive is precisely formulated to provide optimal tackiness without leaving residue on shoes or equipment wheels. These mats are commonly available in various sizes, including standard doorway dimensions and customizable lengths for specific facility requirements. The manufacturing process adheres to strict quality control standards, ensuring consistent performance and reliability. The mats feature a non-slip backing that keeps them securely in place, while the tear-resistant construction ensures durability even under heavy foot traffic. Their effectiveness in particle removal typically exceeds 99%, making them essential for maintaining cleanliness standards in sensitive manufacturing environments.