high quality cleanroom wiper

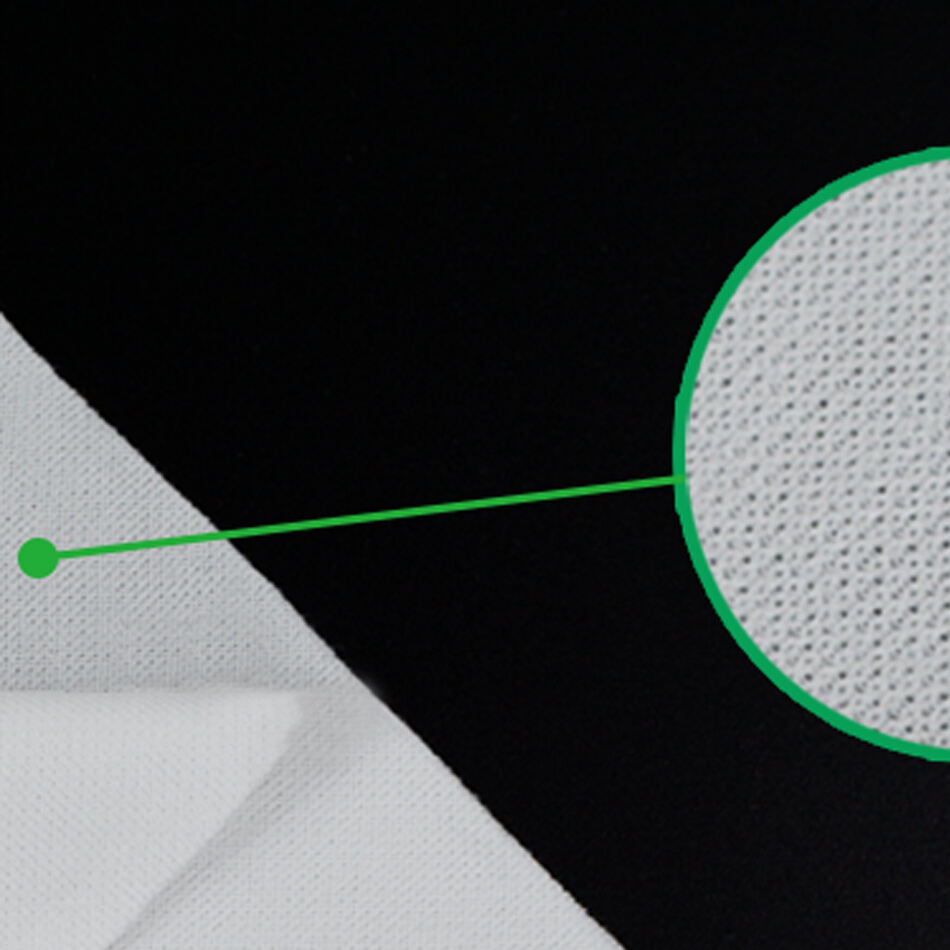

High quality cleanroom wipers represent an essential component in maintaining contamination-free environments across various industries. These specialized wipers are engineered using advanced materials and manufacturing processes to ensure exceptional cleanliness and particle control. Made from ultra-pure materials, typically consisting of polyester or cellulose blends, these wipers undergo rigorous quality control measures to meet stringent cleanroom standards. The wipers feature a unique construction that minimizes particle generation and provides superior absorption capabilities while maintaining structural integrity during use. Their design incorporates specialized edge sealing techniques to prevent fiber release and ensure consistent performance across various applications. These wipers demonstrate remarkable versatility in cleanroom environments, serving multiple functions from equipment cleaning to surface preparation and spill control. They are specifically engineered to handle various solvents and chemicals without degradation, making them ideal for critical cleaning processes in semiconductor manufacturing, pharmaceutical production, and medical device assembly. The wipers' controlled manufacturing environment and sophisticated testing procedures ensure compliance with ISO standards and other regulatory requirements, providing users with reliable and consistent performance in maintaining cleanroom integrity.