cleanroom wiper for sale

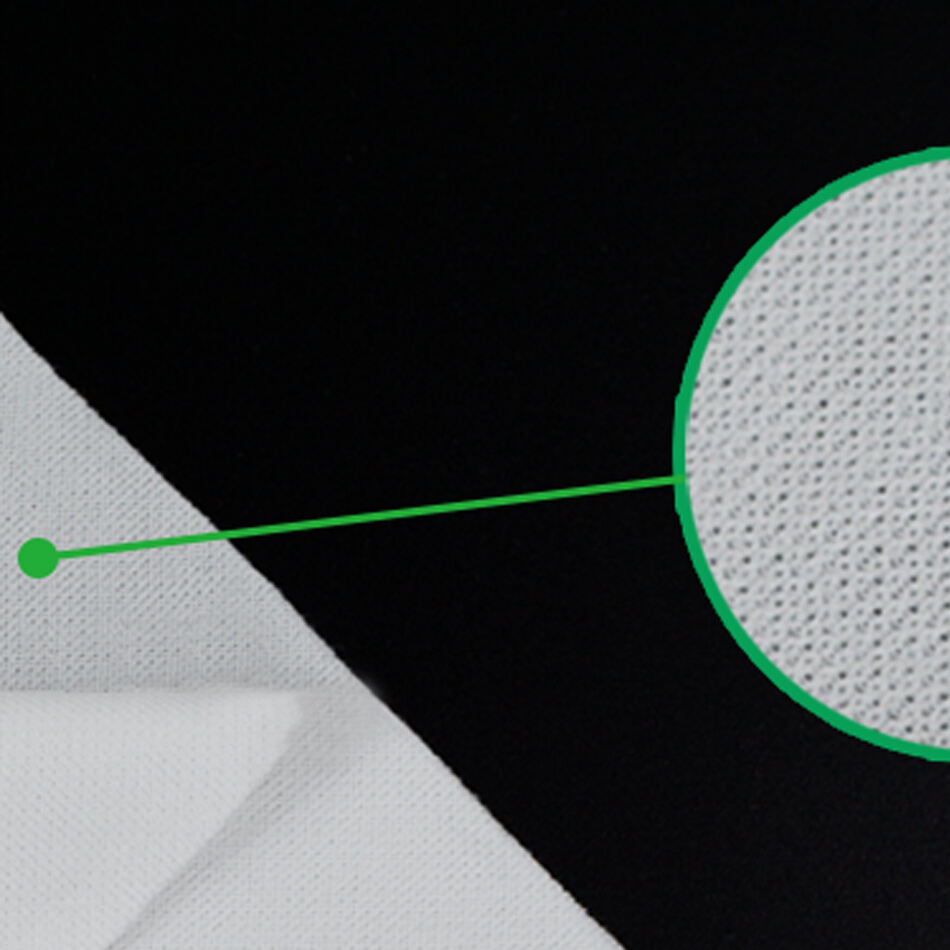

The cleanroom wiper represents a critical component in maintaining controlled environments, engineered specifically for demanding applications in industries requiring pristine conditions. These specialized wipers are manufactured using advanced materials and precise construction techniques to ensure optimal particle removal and minimal lint generation. The wiper features a unique blend of synthetic fibers, carefully processed to eliminate contaminants and provide superior absorption capabilities. Each wiper undergoes rigorous quality control measures, including particle counting and chemical analysis, to meet stringent cleanliness standards. The product's edge-sealing technology prevents fiber release during use, while its uniform construction ensures consistent performance across every application. These wipers are available in various sizes and configurations to accommodate different cleaning requirements, from general surface wiping to precision cleaning of sensitive equipment. Their versatility makes them ideal for use in semiconductor manufacturing, pharmaceutical production, biotechnology laboratories, and other controlled environments where contamination control is paramount. The material composition allows for excellent chemical compatibility, making these wipers suitable for use with various cleaning agents and solvents commonly used in cleanroom operations.