reliable esd cleanroom wiper

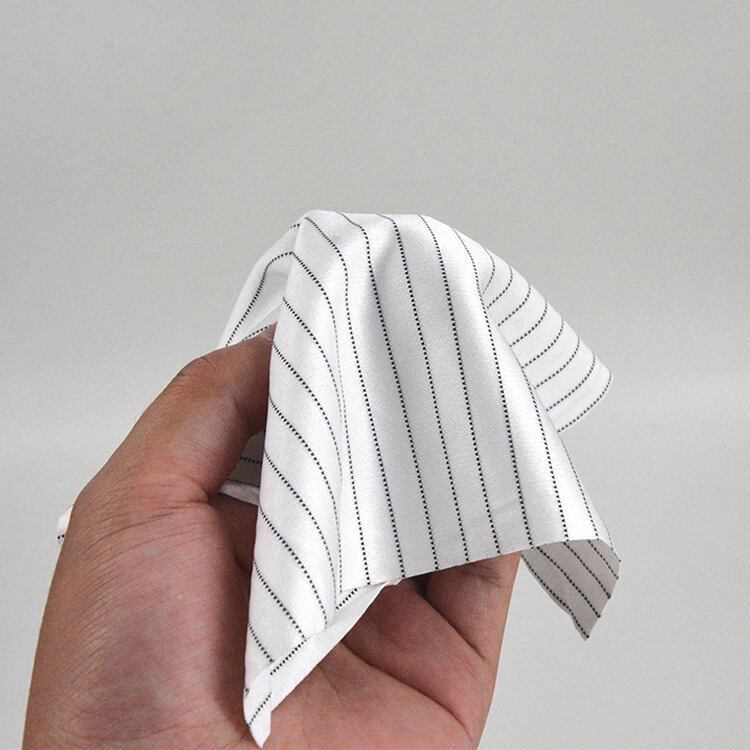

The reliable ESD cleanroom wiper represents a crucial tool in contamination control and static-sensitive environments. These specialized wipers are engineered with precise synthetic blends that effectively control electrostatic discharge while maintaining superior cleaning capabilities. The wipers feature a unique construction that combines low particle generation with exceptional absorbency, making them ideal for critical cleaning applications in semiconductor manufacturing, pharmaceutical processing, and other high-tech industries. Each wiper undergoes rigorous quality control testing to ensure consistent surface resistivity measurements and particle counts. The material composition includes specialized synthetic fibers that maintain their ESD properties throughout use, even when exposed to various cleaning solutions. These wipers are designed to meet Class 100/ISO 5 cleanroom standards and offer reliable static dissipative properties with surface resistivity ranging from 10^5 to 10^11 ohms per square. The wipers' edge sealing technology prevents fiber release and maintains structural integrity during use, while their lint-free characteristics ensure no contamination of sensitive surfaces. They are compatible with various solvents and cleaning agents commonly used in cleanroom environments, making them versatile tools for multiple applications.