buy esd cleanroom wiper

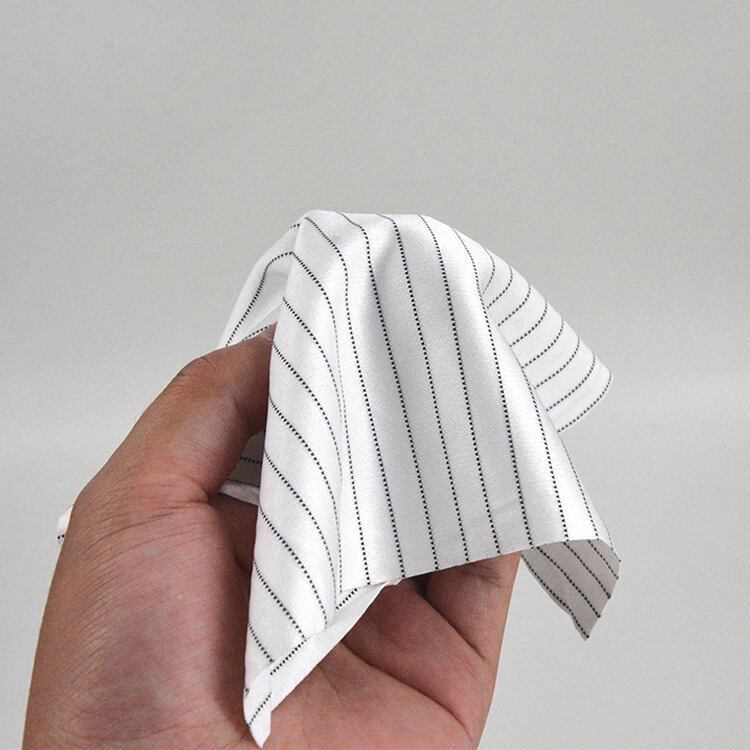

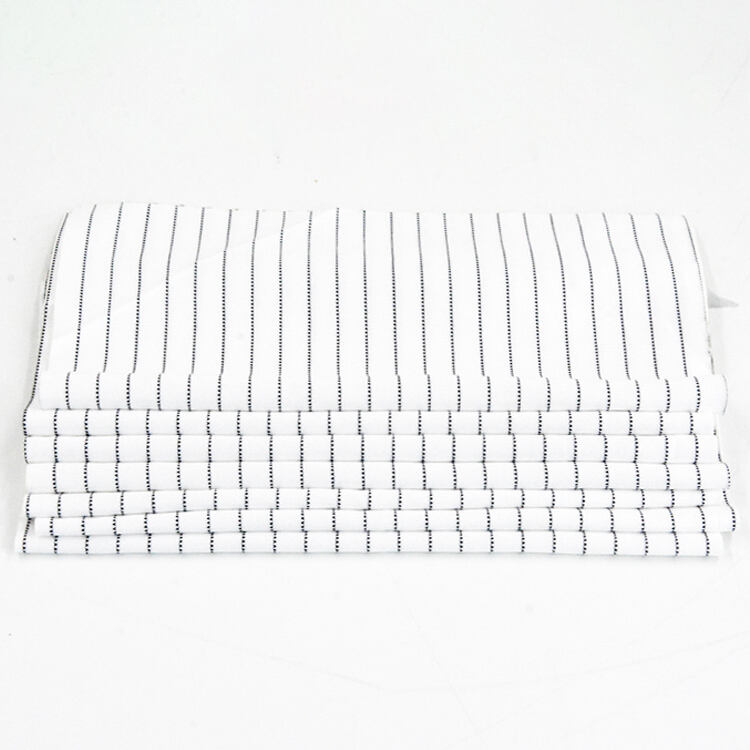

ESD cleanroom wipers are essential tools in controlled environments, specifically designed to maintain cleanliness while preventing electrostatic discharge that could damage sensitive electronic components. These specialized wipers are manufactured using innovative materials that combine superior particle retention capabilities with static-dissipative properties. The wipers feature a unique blend of synthetic fibers treated with specialized compounds to ensure consistent conductivity across the entire surface. They are particularly effective in removing microscopic particles, oils, and other contaminants while maintaining the strict cleanliness requirements of cleanroom environments. The wipers undergo rigorous quality control processes, including particle counting and conductivity testing, to ensure they meet ISO standards for cleanroom use. They are individually packaged to maintain their cleanliness and ESD-safe properties until use. These wipers are available in various sizes and configurations to accommodate different cleaning requirements and are compatible with common cleaning solvents used in cleanroom environments. The material construction ensures minimal particle generation during use, making them ideal for critical cleaning applications in semiconductor manufacturing, electronics assembly, and other sensitive industrial processes.