best cleanroom wiper

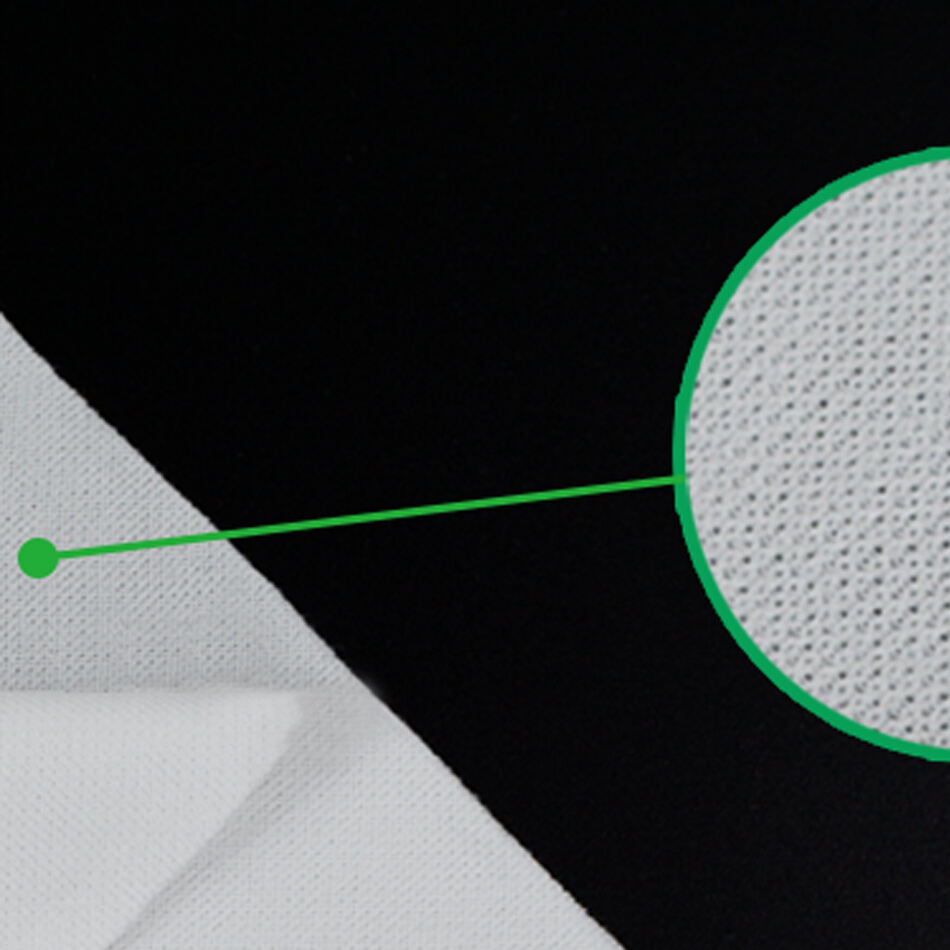

The premium cleanroom wiper represents the pinnacle of contamination control technology, engineered specifically for critical environments requiring the highest standards of cleanliness. This advanced cleaning tool is manufactured using ultra-pure materials and undergoes rigorous processing to ensure minimal particle generation and superior absorbency. The wiper features a unique microfiber construction with precisely controlled fiber lengths and densities, enabling it to effectively capture and retain particles as small as 0.1 microns. Its innovative edge-sealing technology prevents fiber release and ensures consistent performance across the entire surface. The wiper exhibits exceptional chemical compatibility, making it suitable for use with various cleaning agents, including IPA, acetone, and other common solvents. Designed for ISO Class 3-8 cleanrooms, this wiper demonstrates remarkable durability while maintaining its structural integrity throughout use. The product undergoes extensive quality control measures, including particle counting, ion analysis, and extractables testing, ensuring compliance with stringent cleanroom standards. Its versatile applications span semiconductor manufacturing, pharmaceutical production, biotechnology research, and other sensitive manufacturing processes where contamination control is paramount.