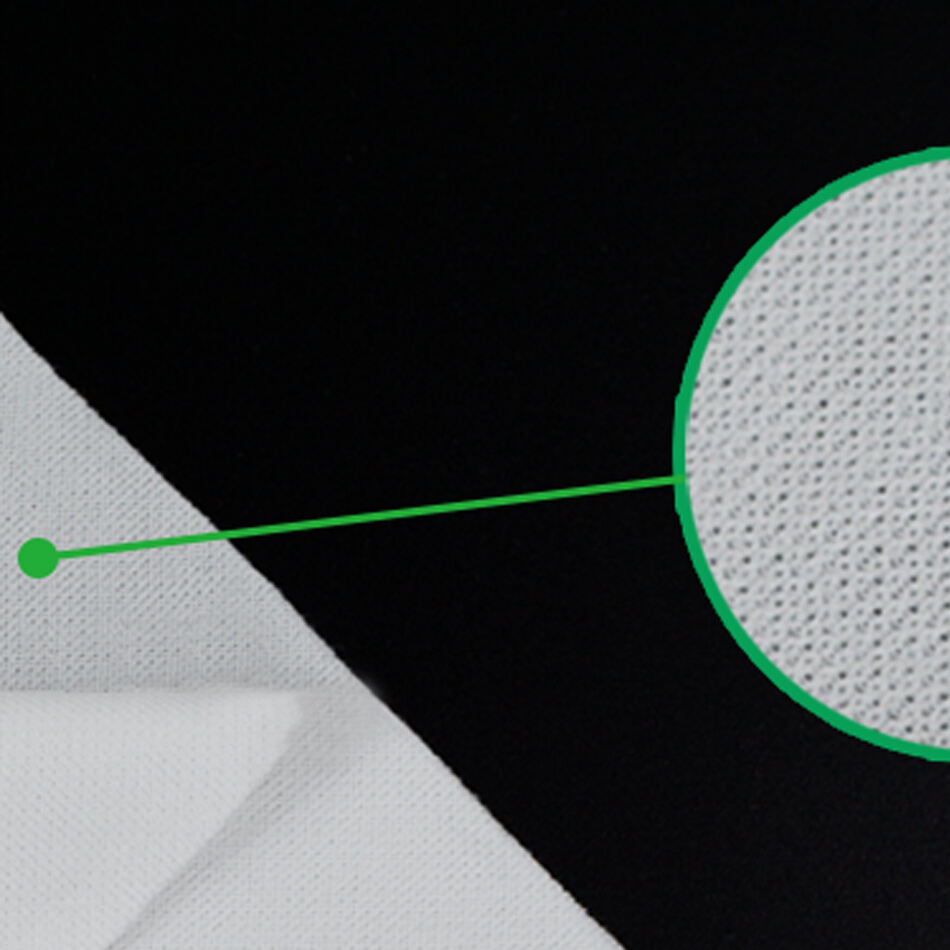

cleanroom microfiber wiper

Cleanroom microfiber wipers represent a crucial advancement in contamination control technology, engineered specifically for critical cleaning applications in controlled environments. These specialized wipers combine ultra-fine synthetic fibers, typically measuring less than 1 denier in diameter, woven into a precise pattern that creates an exceptional cleaning tool. The unique construction enables these wipers to trap and remove particles as small as 0.1 microns, making them significantly more effective than traditional cleaning materials. Each wiper undergoes rigorous manufacturing processes in controlled environments to ensure they meet stringent cleanliness standards and maintain consistently low particle generation. The material composition typically features a blend of polyester and polyamide fibers, processed to create millions of microscopic spaces between fibers that effectively capture and retain contaminants. These wipers are specifically designed for use in ISO Class 3-8 cleanrooms and can be used either dry or with appropriate cleaning solutions. They excel in applications requiring precision cleaning, such as semiconductor manufacturing, pharmaceutical production, aerospace assembly, and sensitive optical equipment maintenance. The wipers maintain their integrity even after multiple uses and laundering cycles, providing a cost-effective solution for long-term cleanroom operations.