best esd sticky mat

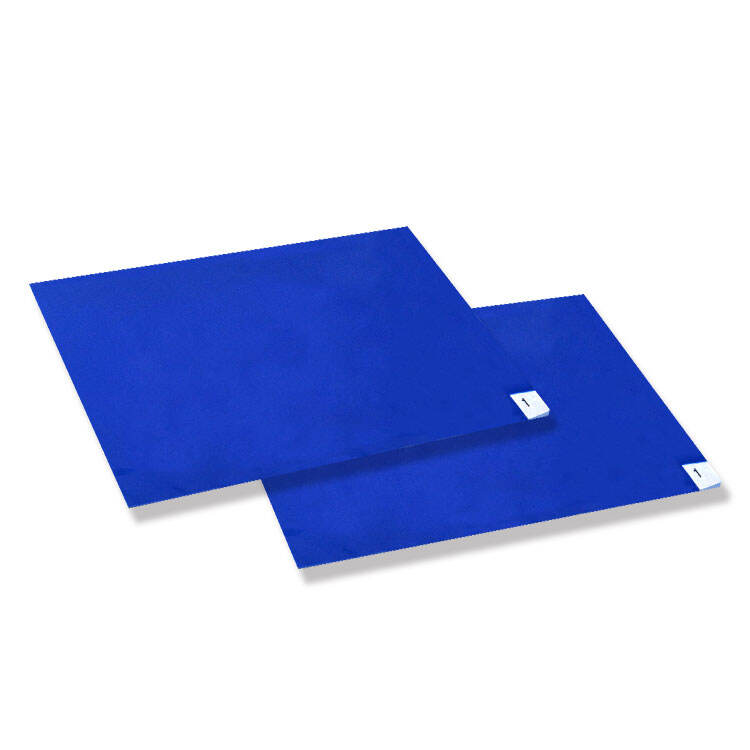

The best ESD sticky mat represents a crucial component in maintaining electrostatic discharge protection in sensitive environments. These specialized mats feature multiple layers of adhesive sheets that effectively capture dust, dirt, and other particulates before they can enter clean rooms or sensitive work areas. The mat's surface is designed with a precise level of tackiness that removes contamination from shoe soles and wheel casters while maintaining consistent ESD protection throughout its lifespan. Each layer is numbered for easy identification and peeling, typically offering 30-40 sheets per mat. The advanced adhesive technology ensures that no residue remains when layers are removed, maintaining a pristine work environment. These mats are engineered to meet strict industry standards for electrical resistance, typically ranging from 108 to 1011 ohms, providing reliable static dissipation. The construction includes a non-slip backing that keeps the mat firmly in place, even under heavy foot traffic. Available in various sizes to accommodate different entrances and walkways, these mats are essential for industries such as electronics manufacturing, pharmaceutical production, and semiconductor fabrication.