best esd wiper

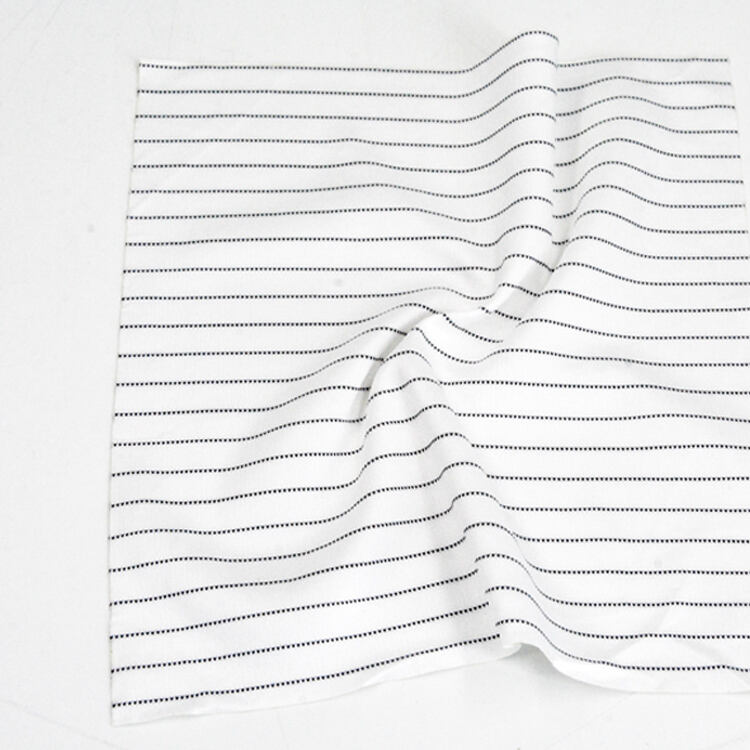

The best ESD wiper represents a cutting-edge solution in cleanroom and sensitive electronics manufacturing environments. This specialized cleaning tool is engineered with advanced static dissipative materials that effectively remove particles while preventing electrostatic discharge, which could damage sensitive electronic components. The wiper features a unique blend of synthetic microfibers that are precisely woven to create an optimal cleaning surface, capable of trapping particles as small as 0.5 microns. The material composition includes specially treated polyester and cellulose fibers that maintain consistent conductivity levels, typically ranging between 10^6 to 10^9 ohms per square. These wipers are specifically designed to meet ISO 14644-1 cleanroom standards and are tested for particle generation, ensuring they release minimal particles during use. The wiper's edge treatment prevents fraying and maintains structural integrity even in demanding cleaning applications. Its versatility makes it ideal for cleaning sensitive electronic components, optical surfaces, and cleanroom equipment while maintaining ESD safety protocols.