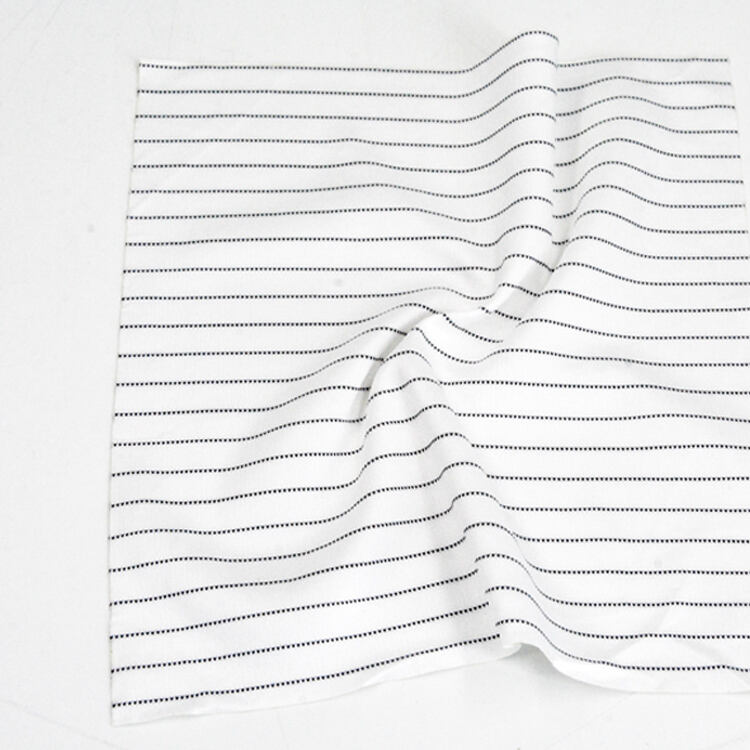

new esd wiper

The new ESD wiper represents a significant advancement in static control technology, offering superior protection against electrostatic discharge in sensitive manufacturing environments. This innovative cleaning solution combines advanced microfiber technology with specialized conductive fibers, creating a highly effective tool for removing particulates while simultaneously preventing static buildup. The wiper's unique construction features a multi-layer design that includes a static dissipative outer layer and a highly absorbent inner core, enabling it to trap and hold both dry and wet contaminants effectively. Engineered for use in cleanroom environments up to ISO Class 4, the wiper maintains its performance integrity even after multiple uses, making it both cost-effective and environmentally responsible. The material composition ensures consistent static dissipation properties throughout the entire wiping process, with surface resistivity measurements ranging from 10^5 to 10^11 ohms per square. This advanced wiper is particularly valuable in electronics manufacturing, semiconductor production, and other precision industries where static control is crucial. The product's edge treatment prevents particle generation and fiber release, while its low-ion content makes it safe for use on sensitive components and surfaces.