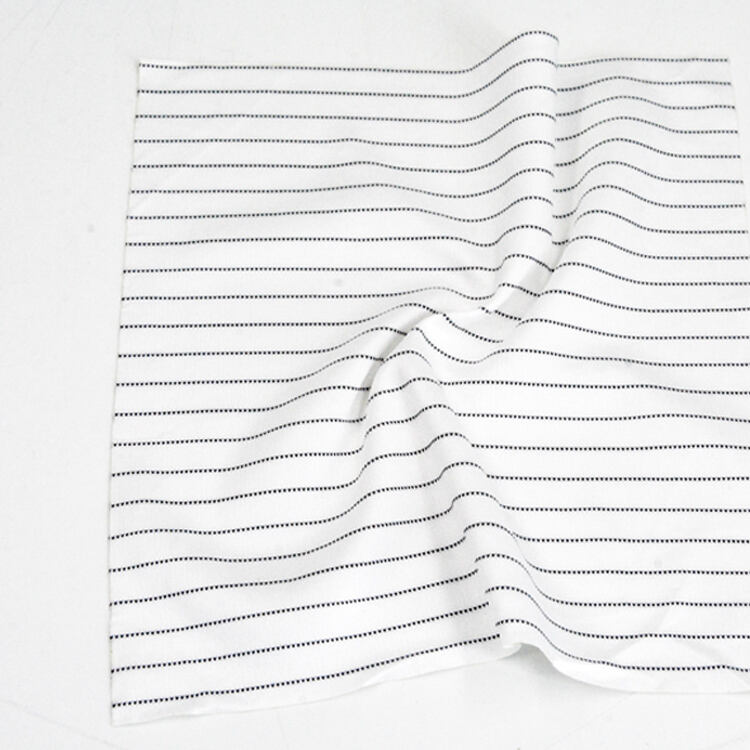

esd wiper for cleanroom use

ESD wipers for cleanroom use represent a critical component in maintaining contamination-free environments while preventing electrostatic discharge. These specialized wipers are engineered with advanced conductive fibers and materials that effectively dissipate static electricity while maintaining superior cleaning capabilities. The wipers feature a unique construction that combines low particle generation with reliable static control properties, making them ideal for sensitive electronic manufacturing, semiconductor production, and other high-tech industrial applications. These wipers typically incorporate carbon or other conductive materials within their fabric structure, ensuring consistent static dissipative properties throughout the entire wiper, not just on the surface. They are specifically designed to meet the stringent requirements of ISO Class 3-6 cleanrooms and offer excellent particle entrapment capabilities while maintaining their ESD-safe characteristics even after multiple uses. The wipers are processed and packaged in cleanroom environments to ensure they meet the necessary cleanliness standards right from the start. Their versatility allows them to be used with various cleaning solutions without compromising their static dissipative properties, making them essential tools in maintaining both cleanliness and static safety in critical environments.