esd microfiber cleaning wiper

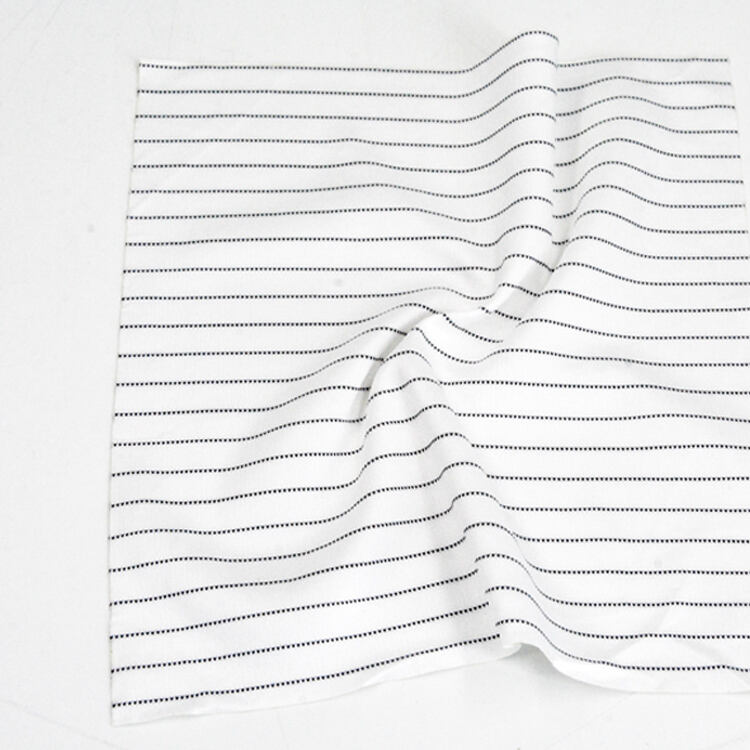

The ESD microfiber cleaning wiper represents a cutting-edge solution in precision cleaning technology, specifically engineered for sensitive electronic components and cleanroom environments. This advanced cleaning tool combines the superior cleaning capabilities of microfiber technology with electrostatic discharge protection, making it indispensable in industries where static control is crucial. The wiper features a unique blend of specialized microfibers that are precisely constructed to trap and remove particles as small as 0.1 microns while maintaining consistent ESD protection throughout its lifetime. Each fiber is treated with innovative conductive materials that ensure static dissipation, preventing potential damage to sensitive electronic components during cleaning operations. The wiper's construction includes a distinctive knitting pattern that enhances its particle collection efficiency while minimizing lint and particle generation. These wipers are specifically designed to maintain their effectiveness across multiple cleaning cycles, offering exceptional durability without compromising their ESD properties or cleaning performance. The material composition ensures optimal absorption of both water-based and solvent-based solutions, making them versatile for various cleaning applications in controlled environments.