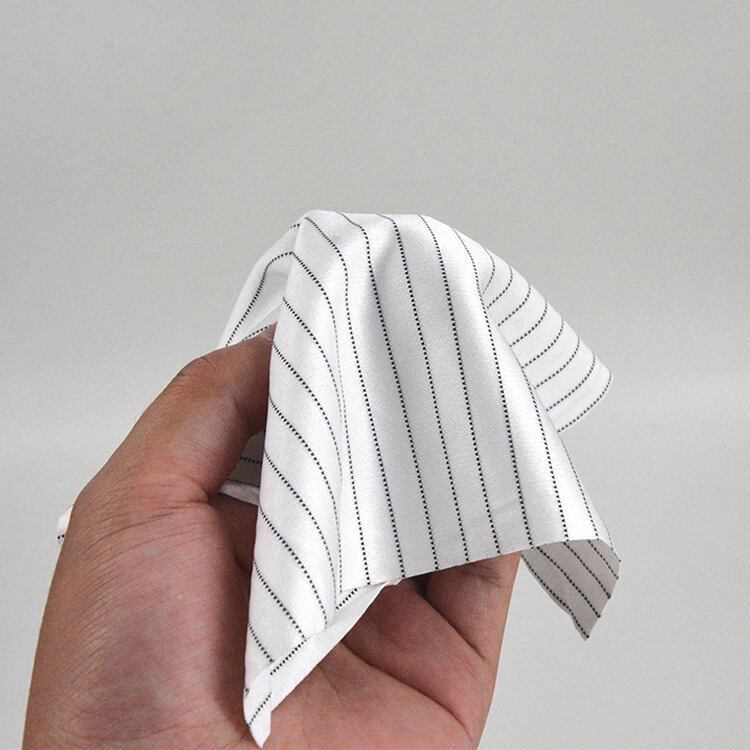

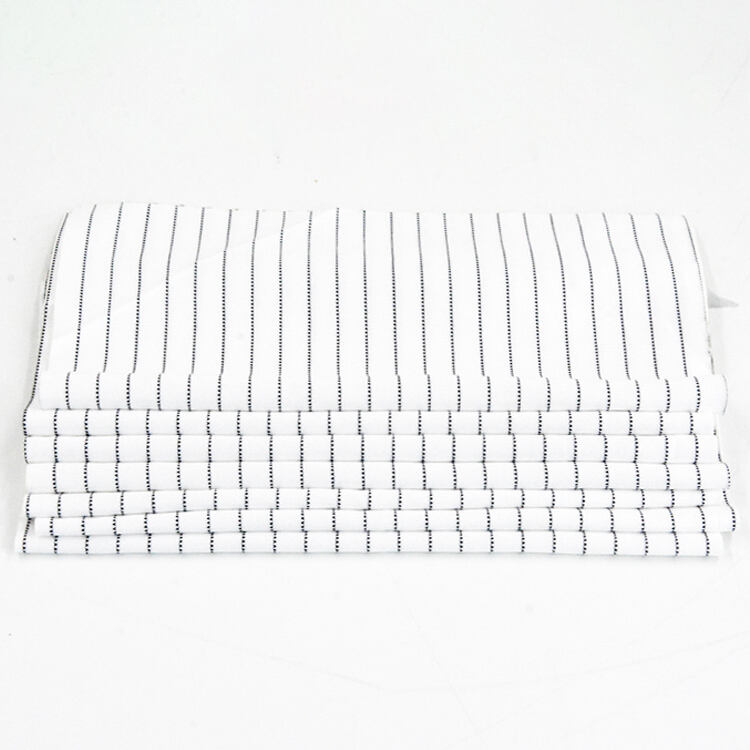

esd cleanroom wiper manufacturer

An ESD cleanroom wiper manufacturer specializes in producing high-performance cleaning materials essential for controlled environments and sensitive electronic manufacturing processes. These specialized wipers are engineered with advanced electrostatic discharge protection capabilities, preventing potential damage to sensitive electronic components during cleaning operations. The manufacturing process involves state-of-the-art technology that ensures consistent quality and reliable performance across all products. These wipers are specifically designed to meet the stringent requirements of ISO-certified cleanrooms, featuring low particle generation, excellent absorbency, and superior static dissipative properties. The manufacturer employs advanced materials and precise production techniques to create wipers that effectively remove contaminants while maintaining the integrity of sensitive electronic components. Their products undergo rigorous quality control measures, including particle counting, electrical resistance testing, and durability assessments. The facility itself operates under strict cleanroom conditions to prevent contamination during the manufacturing process, ensuring that each wiper meets or exceeds industry standards for cleanliness and static control.