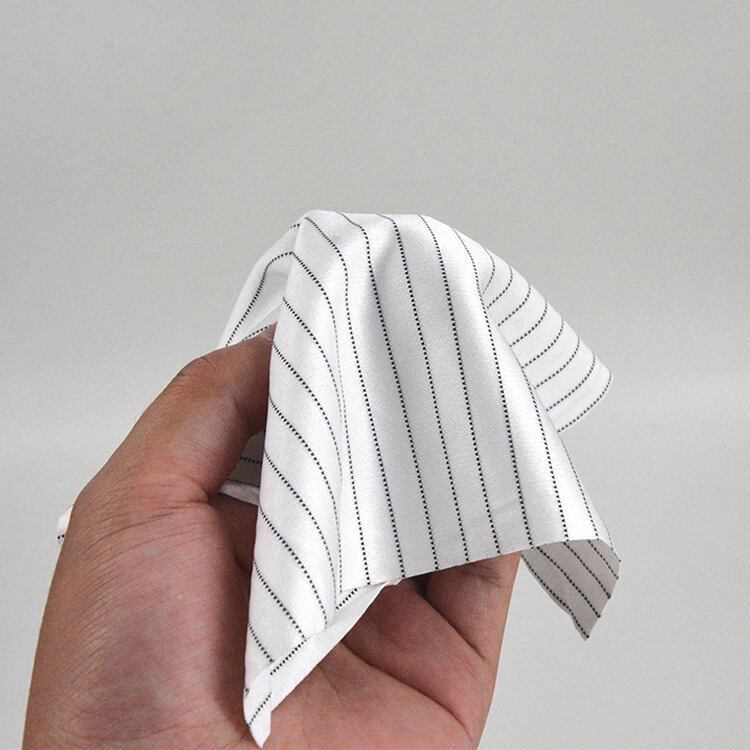

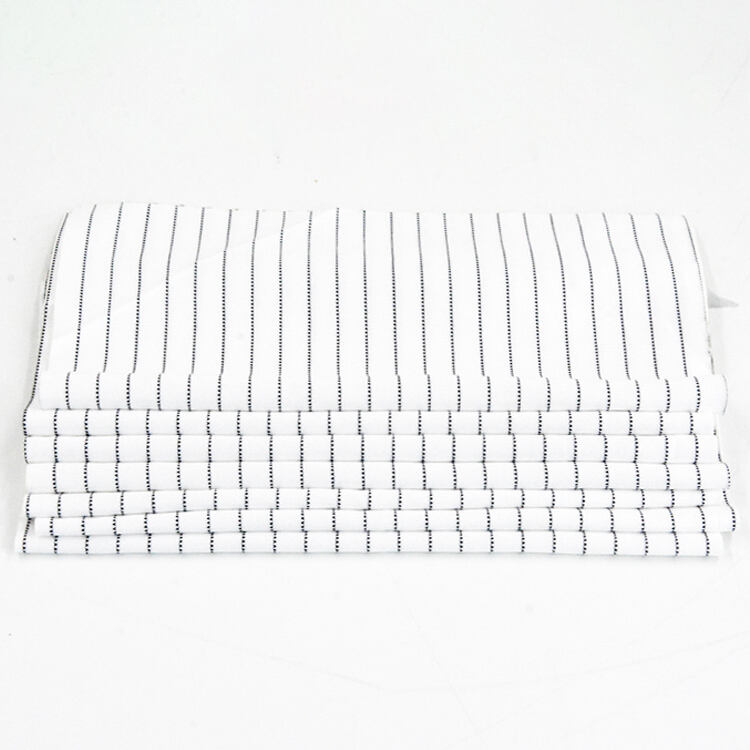

esd cleanroom wiper

ESD cleanroom wipers represent a crucial component in maintaining controlled environments, specifically designed to prevent electrostatic discharge while ensuring superior cleaning performance. These specialized wipers are engineered with conductive fibers that effectively dissipate static charges, making them essential for sensitive electronic manufacturing and cleanroom operations. The wipers feature a unique blend of synthetic materials treated with specialized anti-static agents, ensuring consistent electrical conductivity throughout their entire surface. They excel in removing microscopic particles, oils, and contaminants while maintaining their static-dissipative properties. The construction typically involves a combination of polyester and cellulose fibers, processed under stringent conditions to meet cleanroom standards. These wipers maintain their effectiveness across a wide range of temperatures and humidity levels, making them versatile for various applications. They are particularly valuable in industries such as semiconductor manufacturing, aerospace, pharmaceutical production, and precision electronics assembly. The wipers undergo rigorous quality control measures to ensure they meet ISO standards for particle generation, electrostatic discharge protection, and cleanliness levels. Their durability allows for extended use without degradation of their static-dissipative properties, providing cost-effective solutions for cleanroom maintenance.