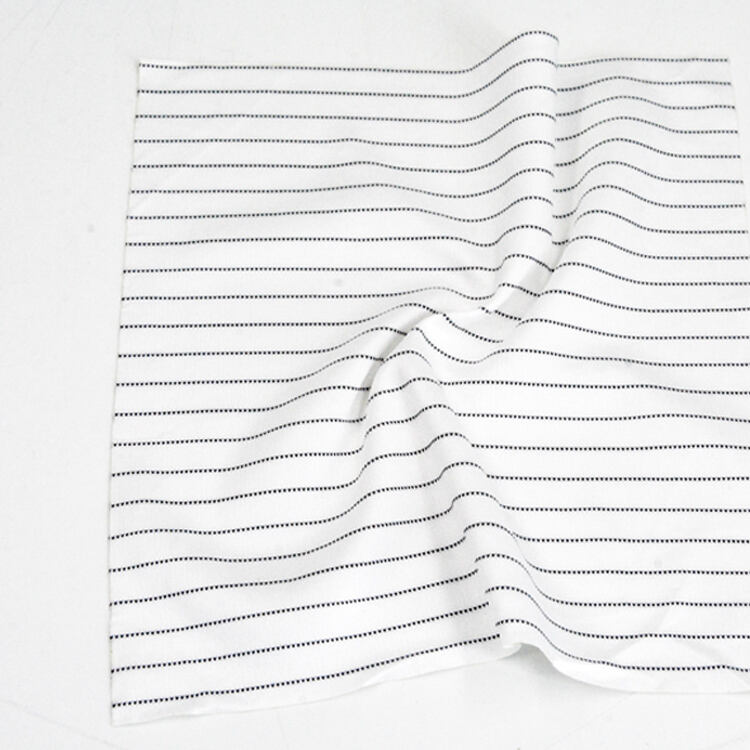

reusable esd wiping cloth

The reusable ESD wiping cloth represents a significant advancement in static-sensitive environments, offering reliable protection against electrostatic discharge while maintaining exceptional cleaning capabilities. These specialized cloths are engineered with innovative conductive fibers interwoven throughout the fabric, creating a consistent and reliable static dissipative surface. The material composition typically includes a blend of polyester and carbon fibers, ensuring both durability and effective static control. With their ability to effectively remove particles as small as 0.5 microns, these cloths are ideal for cleaning sensitive electronic components, cleanroom equipment, and precision instruments. The cloths maintain their ESD properties through hundreds of wash cycles, making them both cost-effective and environmentally sustainable. They are specifically designed to work in controlled environments with humidity levels between 30% and 70%, and can effectively operate in temperatures ranging from -10°C to 60°C. The unique construction of these wiping cloths ensures they remain lint-free and non-abrasive, protecting delicate surfaces while providing thorough cleaning performance. Their versatility extends to various industries, including semiconductor manufacturing, electronics assembly, medical device production, and aerospace applications.