buy esd wiper

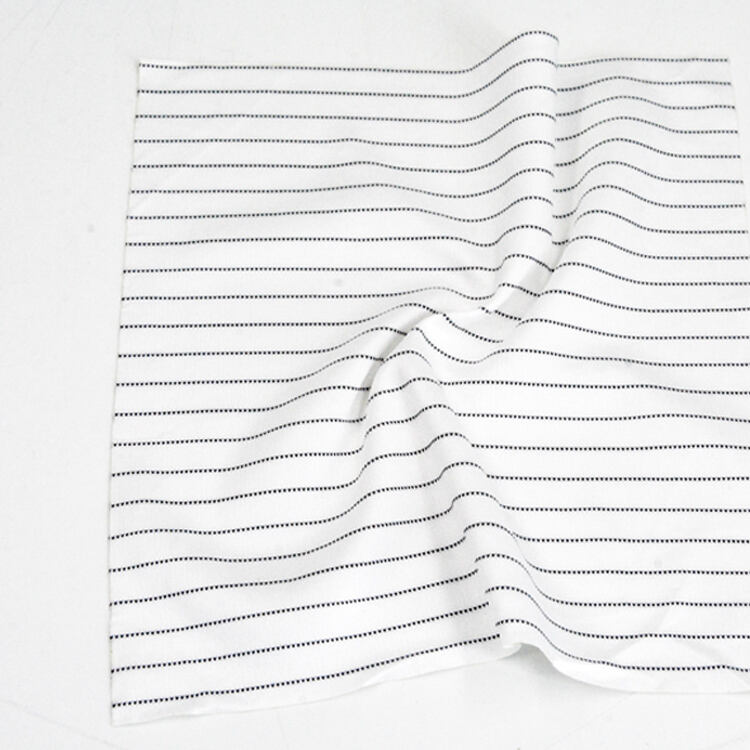

The ESD wiper is an essential tool designed specifically for cleanroom environments and sensitive electronic manufacturing facilities. This specialized cleaning implement combines advanced static-dissipative properties with superior cleaning capabilities to ensure safe and effective maintenance of critical surfaces. The wiper features a unique blend of synthetic microfibers treated with specialized conductive materials, enabling it to effectively remove particles while simultaneously preventing the buildup of static electricity. These wipers are engineered to meet stringent cleanliness standards, typically achieving a particle count well below industry requirements. The material composition includes uniformly distributed carbon or stainless steel fibers that create a continuous conductive network throughout the wiper, ensuring consistent static dissipation. Available in various sizes and packaging options, these wipers are suitable for diverse applications, from cleaning sensitive electronic components to maintaining cleanroom equipment. Each wiper undergoes rigorous quality control testing to verify its static-dissipative properties and particle retention capabilities, making it an indispensable tool for industries where static electricity and contamination control are paramount.