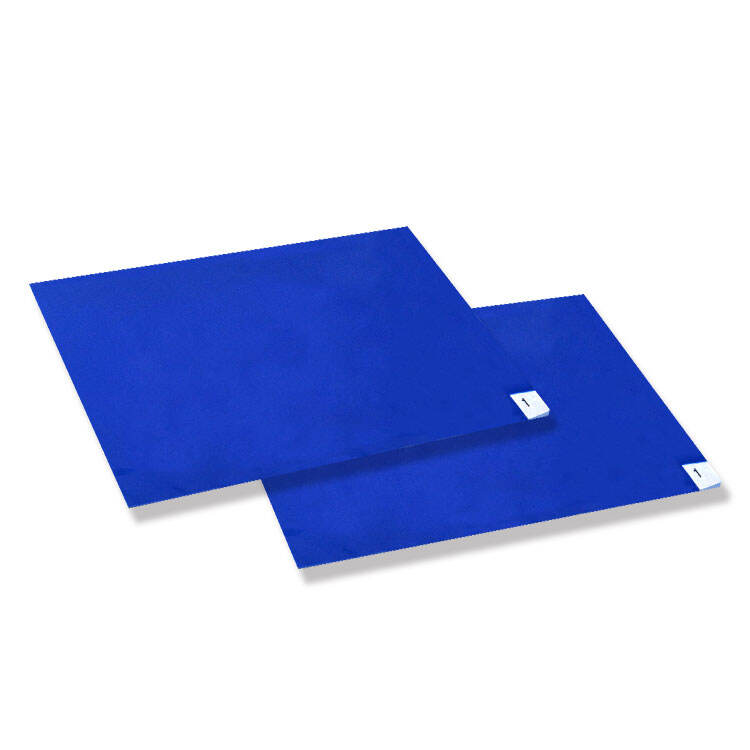

esd sticky mat factory

The ESD sticky mat factory represents a state-of-the-art manufacturing facility dedicated to producing high-quality electrostatic discharge protective floor mats. This advanced facility combines cutting-edge automation technology with precise quality control systems to create reliable contamination control solutions. The factory utilizes specialized polymer processing equipment and automated layering systems to produce mats with consistent adhesive properties and optimal static dissipative characteristics. The production line incorporates multiple testing stations that verify the electrical resistance and adhesive strength of each mat, ensuring compliance with international ESD standards. The facility's clean room environment maintains strict control over particulate contamination during the manufacturing process, while advanced coating systems apply the precise amount of adhesive needed for optimal performance. The factory's production capacity can be scaled to meet varying demand levels, with multiple production lines capable of manufacturing different mat sizes and specifications simultaneously. Quality assurance protocols include regular material testing, environmental monitoring, and detailed documentation of production parameters. The facility also features advanced packaging systems that protect the mats during storage and shipping, maintaining their effectiveness until deployment at customer locations.