esd wiper manufacturer

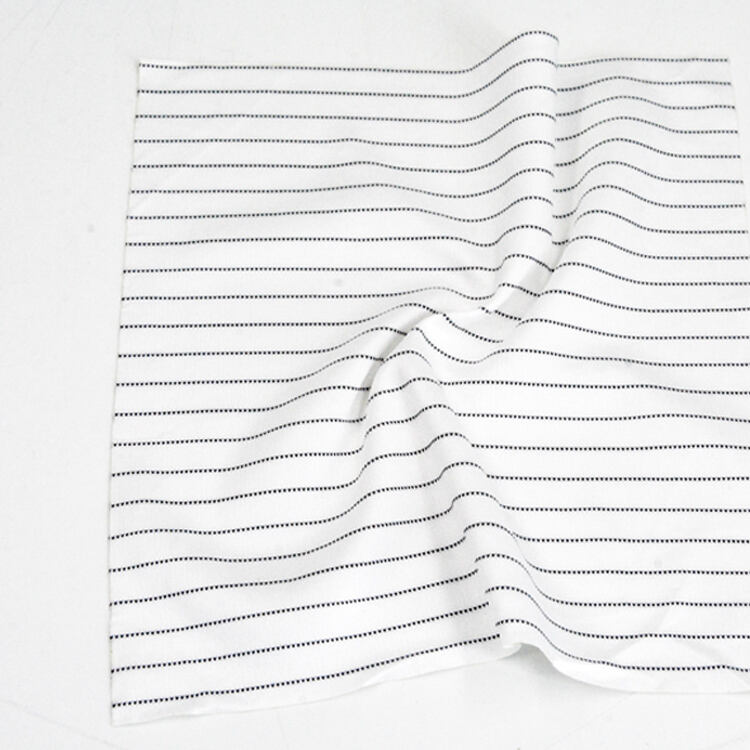

An ESD wiper manufacturer specializes in producing high-quality antistatic cleaning materials essential for sensitive electronic environments. These specialized manufacturers employ advanced production technologies to create wipers that effectively remove contaminants while preventing electrostatic discharge, which can damage delicate electronic components. The manufacturing process involves utilizing specialized materials, such as polyester blends and microfiber, treated with proprietary antistatic agents to ensure consistent ESD protection. These facilities maintain strict quality control measures, including cleanroom environments and regular testing protocols, to guarantee their products meet international ESD safety standards. The manufacturing process incorporates cutting-edge automation systems for precise material cutting, treating, and packaging, ensuring uniformity and reliability across all products. These manufacturers typically offer a comprehensive range of ESD wiping solutions, from general-purpose cleanroom wipes to specialized formats for specific applications in industries such as semiconductor manufacturing, electronics assembly, and medical device production. Their production capabilities often include customization options to meet specific customer requirements, such as size specifications, packaging configurations, and specialized treatments for particular cleaning applications.