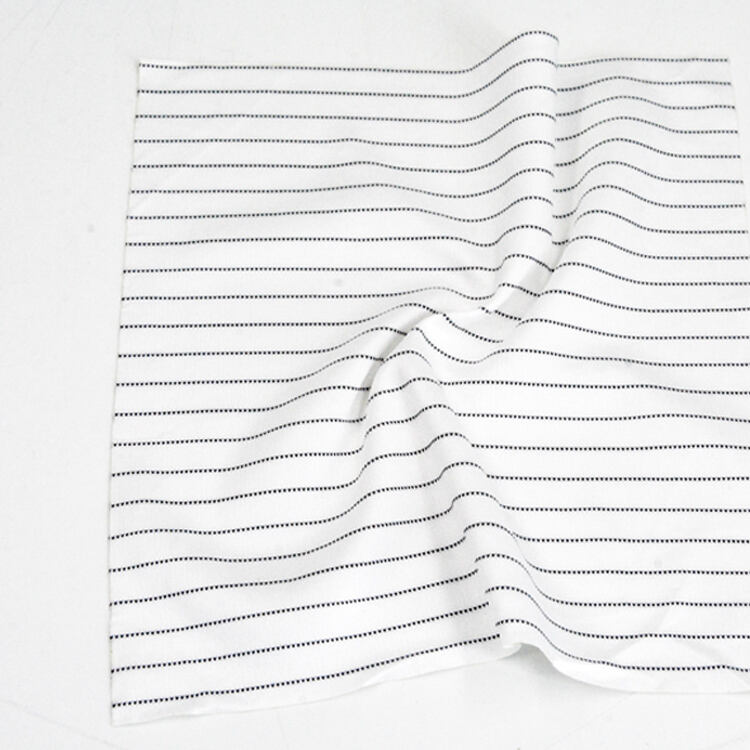

high quality esd wiper

The high quality ESD wiper represents a cutting-edge solution in cleanroom and electronics manufacturing environments, engineered specifically for electrostatic discharge protection. This specialized cleaning tool combines advanced microfiber technology with innovative static-dissipative properties, ensuring safe and effective cleaning of sensitive electronic components and equipment. The wiper features a unique blend of synthetic fibers treated with specialized conductive materials, maintaining a surface resistivity range of 10^6 to 10^9 ohms per square. Its ultra-low particle generation and exceptional absorbency make it ideal for removing contaminants while preventing static buildup. The material construction ensures durability through multiple cleaning cycles, maintaining its ESD-protective properties even after repeated use and laundering. These wipers are available in various sizes and configurations to accommodate different application requirements, from small component cleaning to large surface areas. The controlled manufacturing process ensures consistent quality and performance, meeting ISO Class 4 cleanroom standards and exceeding industry requirements for particle generation and electrostatic discharge protection.