buy cleanroom wiper

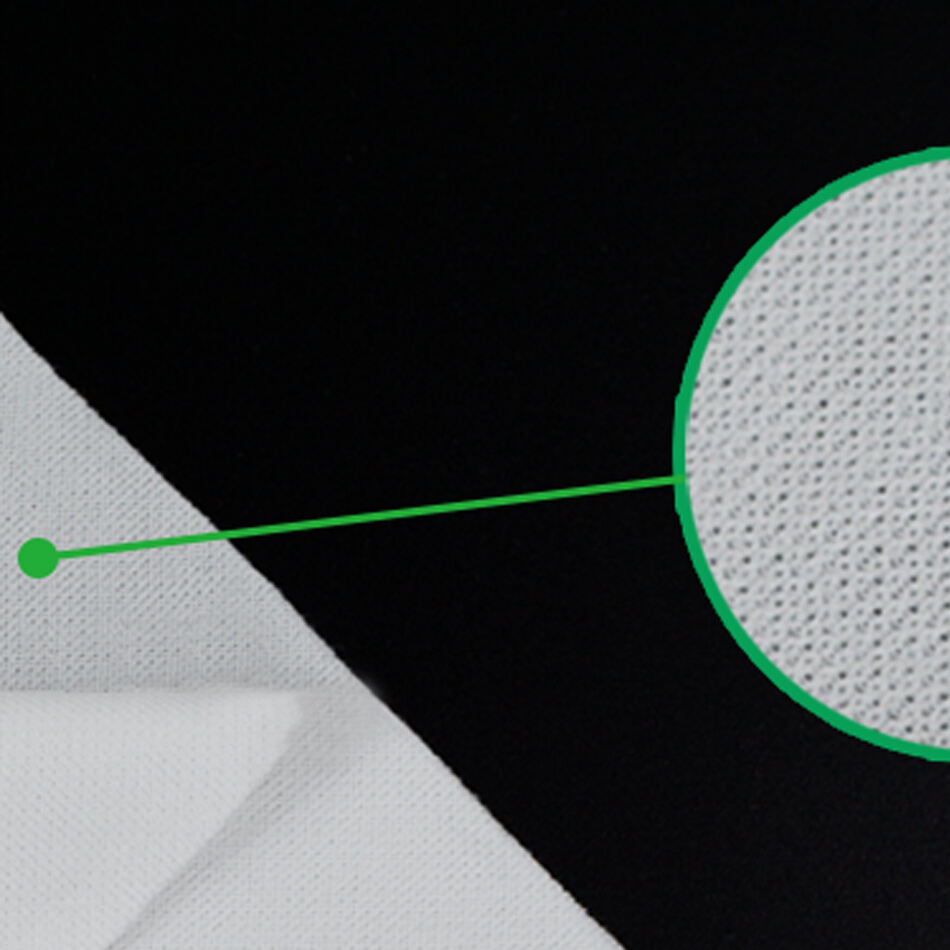

Cleanroom wipers are essential tools in controlled environments, designed to maintain the highest standards of cleanliness and contamination control. These specialized wipers are manufactured using advanced materials and processes to ensure minimal particle generation and superior cleaning performance. The wipers are specifically engineered to meet the stringent requirements of ISO-certified cleanrooms, offering exceptional absorbency, durability, and particle retention capabilities. Made from ultra-pure materials such as polyester or cellulose blends, these wipers undergo rigorous quality control processes to eliminate contaminants. They are perfect for critical cleaning applications in semiconductors, pharmaceutical manufacturing, biotechnology, and aerospace industries. The wipers feature unique characteristics such as laser-cut edges to prevent particle generation, low ionic content to avoid chemical contamination, and specialized textures for effective removal of various contaminants. Available in different sizes and configurations, these wipers can handle diverse cleaning tasks, from general surface wiping to precision cleaning of sensitive equipment. Their controlled packaging ensures maintained cleanliness levels from manufacturing through delivery and use.