esd wiper

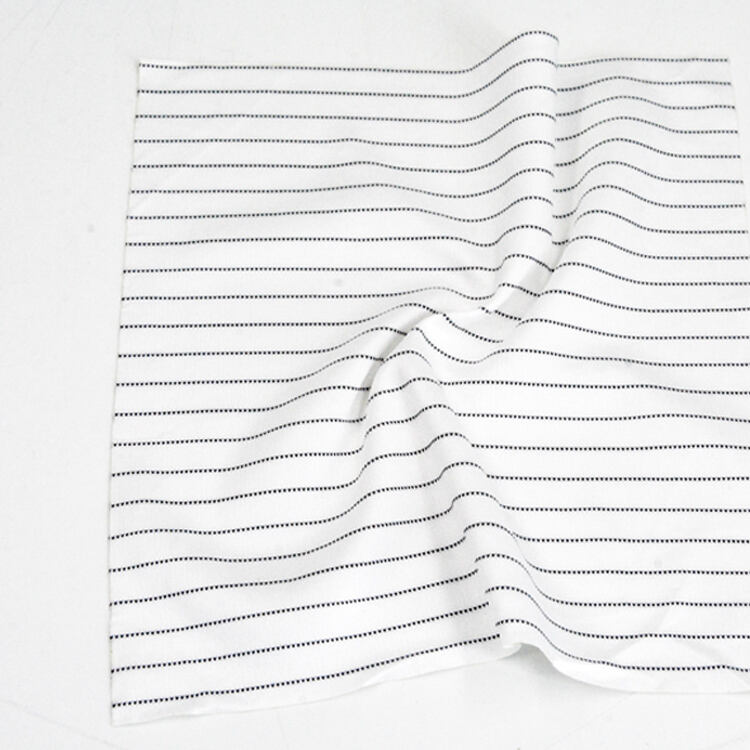

An ESD wiper is a specialized cleaning tool designed to safely remove static electricity and contaminants from sensitive electronic components and surfaces. This essential maintenance tool combines advanced static dissipative materials with precision cleaning capabilities to protect valuable equipment from electrostatic discharge damage. The wiper features a unique construction that typically includes microfiber or similar materials treated with static-dissipative properties, allowing it to effectively clean surfaces while simultaneously neutralizing potentially harmful static charges. These wipers are manufactured under strict quality control conditions to ensure they meet specific electrical resistance requirements and maintain consistent performance. The material composition allows for excellent particle removal efficiency while preventing the generation of additional static charges during the cleaning process. ESD wipers are widely used in cleanroom environments, electronics manufacturing facilities, and other settings where static electricity poses a risk to sensitive components. They are particularly valuable in industries such as semiconductor manufacturing, medical device assembly, and aerospace applications where maintaining static-free environments is crucial. The wipers are designed to be lint-free and non-abrasive, making them safe for use on delicate surfaces such as optical components, circuit boards, and precision instruments. Their versatility extends to both dry and wet cleaning applications, and they can be used with various cleaning solvents without losing their static-dissipative properties.