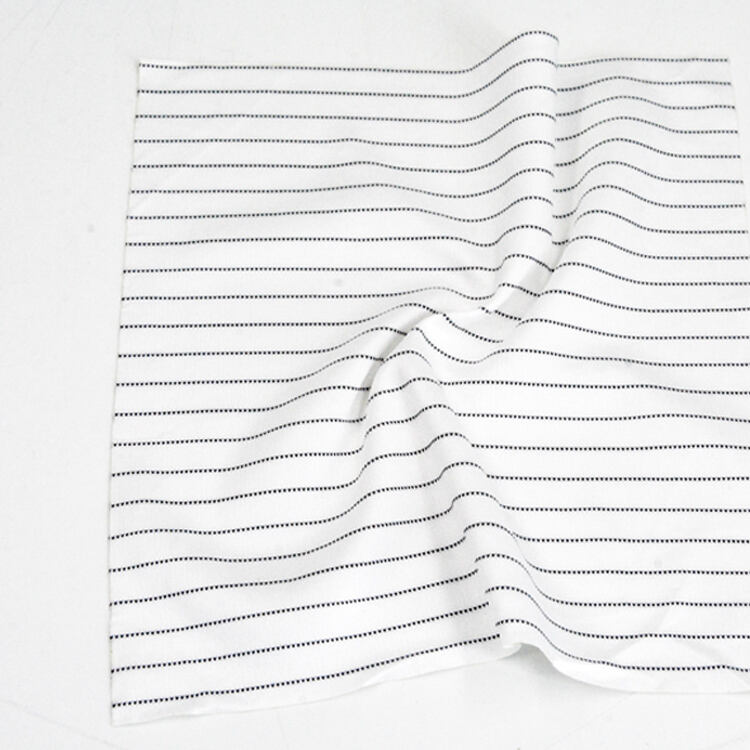

esd wiper made in china

The ESD wiper made in China represents a significant advancement in cleanroom and industrial cleaning technology. These specialized wipers are engineered with precision to effectively control electrostatic discharge while maintaining superior cleaning capabilities. Manufactured using innovative static-dissipative materials, these wipers feature a unique blend of polyester and cellulose fibers treated with specialized anti-static agents. The material composition ensures consistent conductivity across the entire surface, effectively preventing the buildup of static charges during cleaning operations. These wipers maintain an electrical resistance range of 106 to 1011 ohms, making them ideal for handling sensitive electronic components. The manufacturing process incorporates ultrasonic cutting technology, resulting in sealed edges that minimize particle generation and fiber release. With a cleaning efficiency rate of over 99.9%, these wipers excel in removing particles as small as 0.5 microns. They are particularly valuable in semiconductor manufacturing, electronics assembly, and other precision industries where static control is crucial. The wipers undergo rigorous quality control measures, including particle counting and conductivity testing, ensuring consistent performance across every batch.