esd wiper supplier

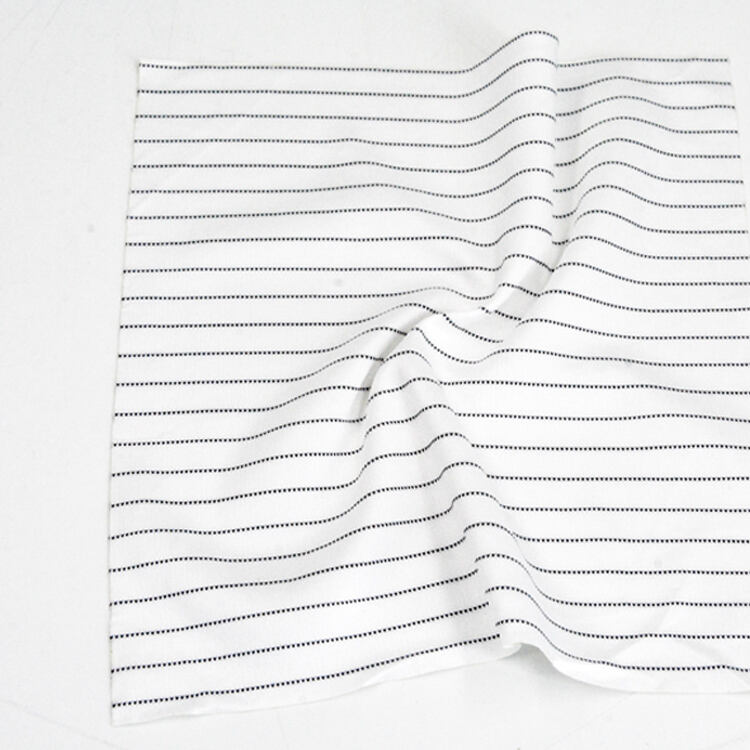

An ESD wiper supplier specializes in providing essential cleaning solutions designed specifically for electrostatic discharge sensitive environments. These specialized wipers are engineered with advanced materials that effectively remove particles and contaminants while preventing static buildup, making them crucial for cleanroom operations and sensitive electronic manufacturing processes. The wipers incorporate specialized fibers and treatments that maintain static dissipative properties throughout their use, typically featuring a surface resistivity range of 10^6 to 10^11 ohms per square. Modern ESD wipers are manufactured in ISO certified cleanroom environments, ensuring they meet strict cleanliness standards and are free from harmful particles that could damage sensitive components. These wipers come in various sizes and configurations, from small precision cleaning tools to larger surface cleaning solutions, all designed to maintain the integrity of ESD protected areas. The technology behind these wipers includes advanced fiber blending techniques, specialized chemical treatments, and rigorous quality control processes to ensure consistent performance and reliability.