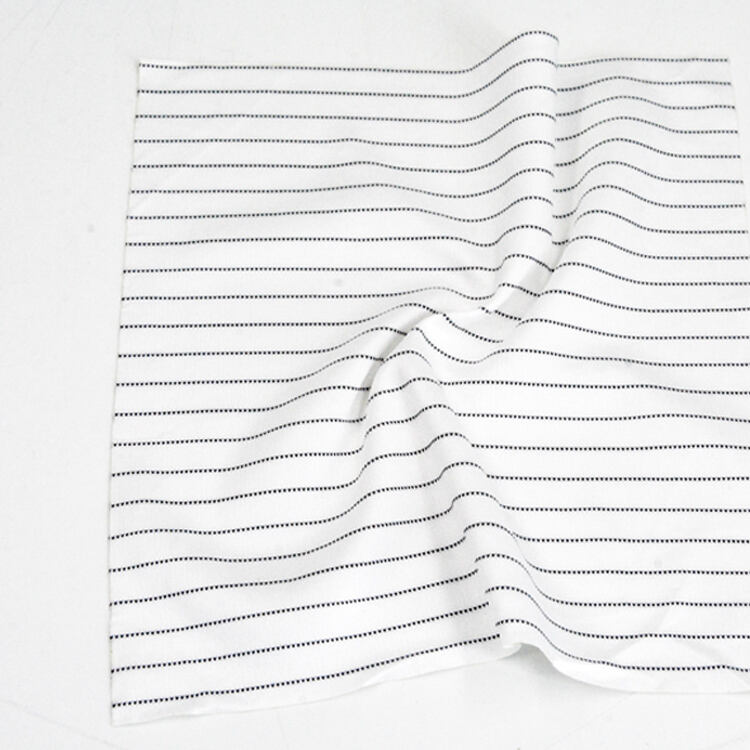

esd safe cleanroom wiper

ESD safe cleanroom wipers represent a crucial component in maintaining contamination-free environments while preventing electrostatic discharge damage. These specialized wipers are engineered with advanced materials that combine superior cleaning capabilities with static-dissipative properties. The wipers are manufactured using a blend of synthetic fibers treated with proprietary antistatic agents, ensuring consistent electrical resistance across the entire surface. They effectively remove particles, debris, and contaminants while maintaining a controlled level of static discharge, making them ideal for sensitive electronic manufacturing environments. The wipers feature exceptional particle retention capabilities and maintain their integrity even when exposed to common cleaning solvents. Their unique construction allows for both dry and wet cleaning applications, with minimal fiber or particle generation during use. The material composition ensures consistent performance across varying humidity levels, maintaining its ESD-safe properties throughout its operational lifecycle. These wipers are specifically designed to meet cleanroom standards, with options available for different ISO class environments. They come in various sizes and packaging options to accommodate different application requirements, from small precision cleaning tasks to larger surface areas.